Introduction

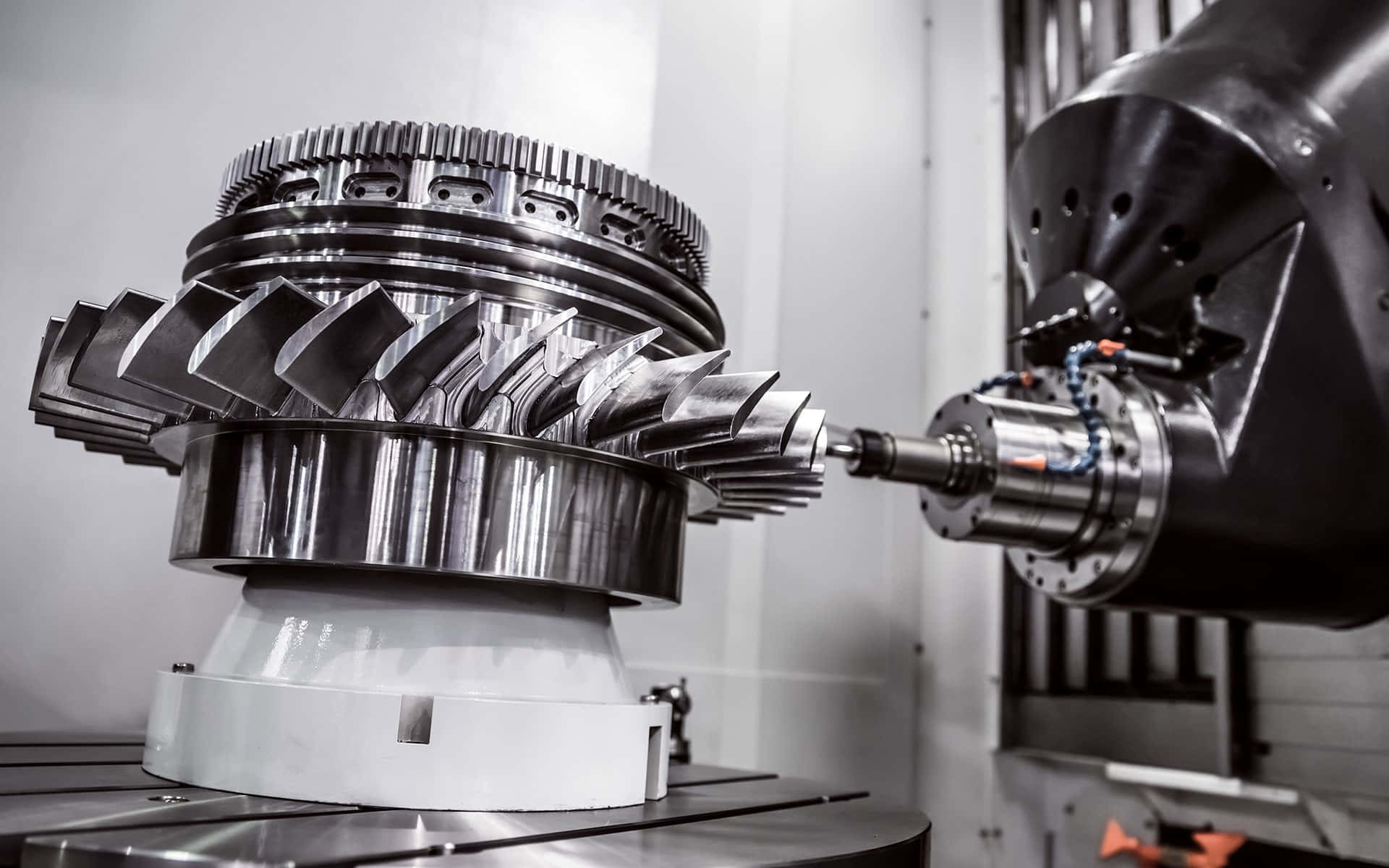

In today’s fast-paced manufacturing world, efficiency and precision are crucial. Horizontal machining center (HMCs) have become the preferred choice for many industries. These machines offer high-speed processing, better chip evacuation, and enhanced productivity. Compared to vertical machining centers (VMCs), HMCs provide superior performance, making them essential for modern production lines.

Enhanced Productivity and Efficiency

One of the biggest reasons manufacturers choose HMCs is their high productivity. These machines allow for multiple operations in a single setup, reducing downtime. With a horizontal spindle orientation, HMCs improve material handling, allowing for quicker part changes. The automatic pallet changer (APC) feature further enhances efficiency by enabling operators to load and unload parts while the machine continues running. This seamless operation increases throughput and reduces labor costs.

Superior Chip Evacuation

Chip evacuation is a critical factor in machining operations. HMCs have a natural advantage due to gravity-assisted chip removal. Unlike VMCs, where chips often accumulate and cause overheating, HMCs efficiently remove chips, maintaining tool longevity. Better chip evacuation results in improved surface finish and reduced cycle times. This capability makes HMCs ideal for machining tough materials like titanium and stainless steel.

Improved Tool Life and Cost Savings

Tool wear and breakage can lead to increased operational costs. HMCs help extend tool life by reducing heat buildup and minimizing vibration. The improved stability in horizontal machining ensures precision and consistency. Manufacturers benefit from lower tool replacement costs and improved process reliability. Over time, this results in substantial cost savings and higher profitability.

High Precision and Accuracy

Modern manufacturing demands tight tolerances and precision machining. HMCs deliver exceptional accuracy due to their rigid structure and balanced spindle design. The reduced thermal expansion in HMCs enhances machining consistency, especially for large production runs. Advanced CNC controls further optimize performance, ensuring minimal deviations and repeatable results.

Multi-Sided Machining Capability

Unlike VMCs, which require repositioning for multi-sided machining, HMCs offer better accessibility. The ability to machine multiple sides without manual intervention reduces errors and improves efficiency. This feature is particularly beneficial for complex components that require intricate detailing. By minimizing setups, HMCs enhance part accuracy and streamline production workflows.

Space Optimization and Layout Flexibility

Factory floor space is a valuable asset in modern manufacturing. HMCs require less space compared to multiple VMCs performing the same tasks. Their compact footprint allows manufacturers to maximize their facility layout. Additionally, the automation-friendly design of HMCs makes them compatible with robotic systems, further improving efficiency. The ability to integrate seamlessly with production lines enhances overall workflow optimization.

Versatility in Material Handling

Manufacturers work with a variety of materials, from aluminum to hardened steel. HMCs provide the flexibility to handle different materials with ease. Their robust construction ensures stability during heavy-duty machining operations. This versatility makes them suitable for industries like aerospace, automotive, and medical device manufacturing. With adaptable tooling and fixturing, HMCs accommodate diverse production requirements.

Reduced Operator Fatigue and Safety Benefits

Ergonomics play a crucial role in machining operations. HMCs reduce operator fatigue by minimizing manual handling. The automated features, such as tool changers and pallet systems, reduce physical strain. Enhanced safety mechanisms also protect workers from potential hazards. By improving the working environment, HMCs contribute to a safer and more efficient production process.

Advanced Automation and Smart Technology Integration

Automation is transforming modern manufacturing. HMCs integrate seamlessly with Industry 4.0 technologies, enabling real-time monitoring and predictive maintenance. Smart sensors and IoT connectivity allow manufacturers to optimize machine performance. The ability to connect with digital manufacturing systems ensures data-driven decision-making. This technological advancement enhances productivity and reduces operational downtime.

Conclusion

Double column machining center have revolutionized the manufacturing industry. Their ability to enhance productivity, improve chip evacuation, and ensure precision makes them the preferred choice. With automation-friendly designs and cost-saving benefits, HMCs offer long-term value for manufacturers. As industries continue to evolve, investing in HMCs remains a strategic decision for achieving higher efficiency and profitability.

Leave a Reply