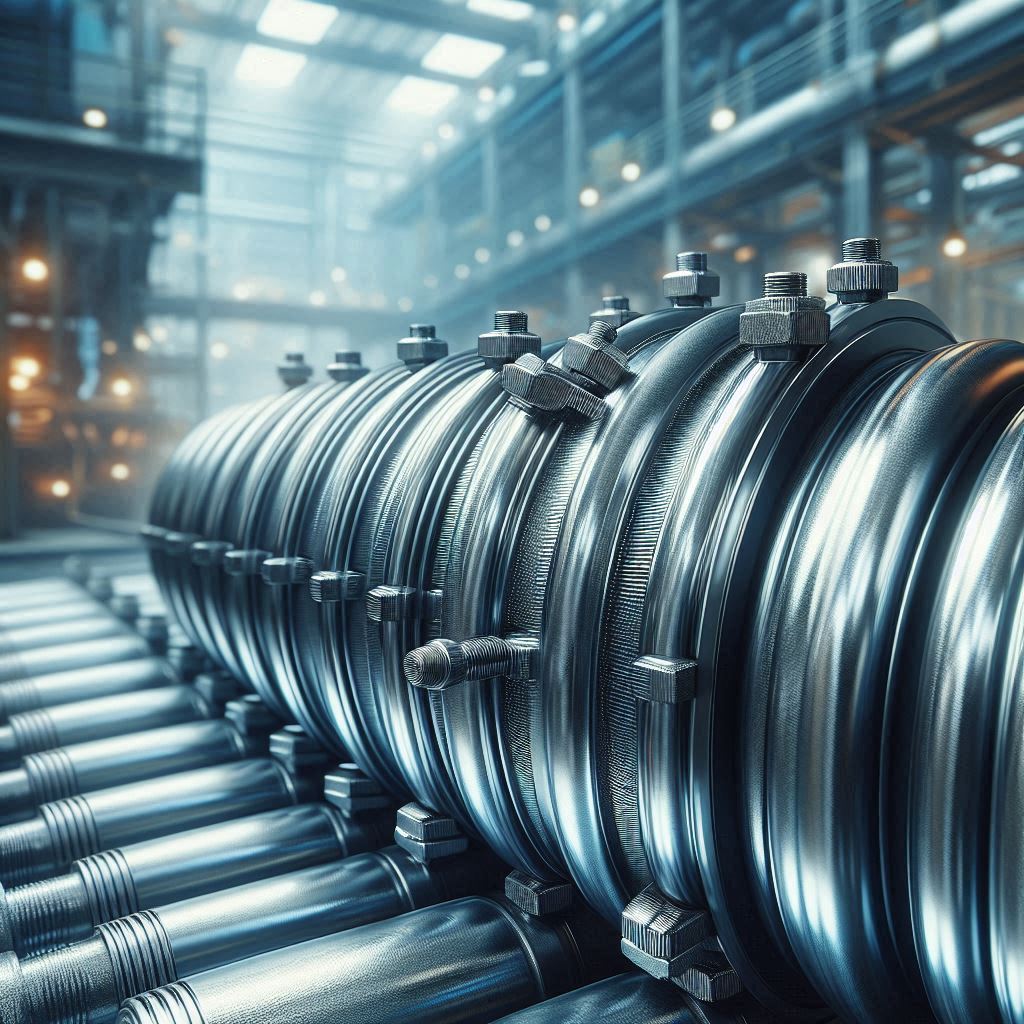

Pipe expansion joint suppliers are the significant players in industrial applications concerning the provision of necessary components for pipe systems with regard to thermal expansion, vibration, and movements. Pipe expansion joints allow the piping system to expand and move or contract with temperature change, pressure fluctuation, or mechanical upsets without transmitting stress to the system or physical damage. Pipe expansion joints allow pipelines to accommodate harsh conditions typical in oil and gas, chemical processing, power generation, and HVAC applications. As a result, pipe expansion joint manufacturers and suppliers produce tough products and an operation of durability and high-performance flexibility, strength, and corrosion resistance. They also manufacture very important specialized joints for custom piping requirements, thus increasing runtime efficiency, safety, and durability in industrial piping systems with almost negligible leakage, rupture, or failure.

Choosing the Right Pipe Expansion Joint Supplier for Your Project

It is absolutely vital and essential that an appropriate pipe expansion joint supplier for the project be selected since it has huge long-term implications regarding reliability, safety, and performance of the piping system itself. On evaluating a manufacturer against the requirements, there comes to mind several aspects, like the manufacturer’s history in a particular field, specialized solutions given to individual working conditions, and quality material utilization with skillful precision manufacturing expertise. An established reputation lies under the safety of the kind of material produced by the like and is abiding by relevant industry standards and certification, ASME or ISO. For this part of this decision, the selection would be more enhanced by comparing the companies based on their on-time delivery performance and system design technical support, and on customer service. Another major consideration would be in the area of the types of expansion joints likely to be available from the manufacturer for specified functions compatible with pressure, temperature, and conditions that the piping system will experience. Based on this, factor in these concerns while making the decision to reduce downtime, maintenance costs, and improve efficiency on your project.

How Pipe Expansion Joint Manufacturers Assist in Improving Safety within High-Pressure Systems

Safety is improved by pipe expansion joint producers in high pressure systems by providing various components that absorb and relieve stresses created from thermal expansion, pressure drop, and mechanic movement. But pipe thermal stresses are built under heavy pressure and applied force such that any active activities, from leakages to ruptures, may occur that are harmful to the whole system. As a result, the expansion joints make provision for accommodation of such movements and relieving that pressure off the system along the pipe, thereby making it less peculiar to damaging effects as well as resultant damages to plant equipment. Certain manufacturers specifically opt for high-strength metallic materials such as stainless steels and temperature-resistant alloys, used advanced design methodologies in the design of joints that dissipate vibrations and absorb shock wave energy in order to prevent catastrophic failures in the system. Thus, uninterrupted safe operation of high-pressure systems can only be assured through the pipe expansion joints manufacturers, guaranteeing the provision of reliable and sturdy customized piping solutions.

Pipe Expansion Joints Manufacturers and Their Impact on Industrial Piping Systems

Pipe expansion joints manufacturer have an impact on the lifespan of industrial piping systems in various ways because they provide what keeps pipelines alive, stable, and non hazardous to industries. Such extensions must be suitably designed and produced to accommodate thermal expansions, pressure drops, and vibration displacements to allow the pipes to engender no stresses, which can easily lead to ruptures or system failure. Protecting the integrity of these sophisticated and highly advanced piping circuits under very harsh aggressive processes is entirely entrusted in the oil and gas, chemical processing, power generation, and HVAC industries with pipe expansion joints. A whole variety of materials exhibiting specific manufacturing process-features of expansion joints merit the anticipation of bespoke solutions. These contribute both to their performance and to reduced maintenance- and downtime costs. Anything that adds extra protection against leaks and pressure-related accidents adds to the contribution made towards the seamless functioning of industrial piping systems worldwide.

Leave a Reply