Custom cable assembly plays a crucial role in various industries, ensuring seamless connectivity, reliable power transmission, and efficient data communication. At SINNHONG ELECTRONICS, we specialize in Custom Cable Assembly in Vietnam, offering high-quality, cost-effective, and innovative solutions tailored to the specific needs of our customers. Our step-by-step process ensures that every cable assembly meets the highest standards of performance, safety, and durability.

Step 1: Understanding Customer Requirements

The initial step we take in Custom Cable Assembly in Vietnam starts with a clear understanding of the customer’s needs. Our team works closely with clients to gather all necessary details, including:

- The intended application of the cable assembly

- Electrical, mechanical, and environmental specifications

- Connector types, wire gauges, and insulation requirements

- Industry compliance and regulatory standards

Our experienced engineering team carefully analyzes these details to ensure the final product meets the customer’s exact specifications.

Step 2: Design and Engineering

Once the requirements are finalized, our expert engineers design a custom cable assembly solution using advanced design software and simulation tools. This step includes:

- Developing a detailed blueprint and circuit layout

- Selecting the most suitable materials and components

- Evaluating signal integrity, voltage, and current requirements

- Ensuring compliance with RoHS 2.0 and ISO 9001 standards

Our Custom Cable Assembly in Vietnam facility is equipped with state-of-the-art engineering tools that allow us to optimize the design for efficiency, durability, and cost-effectiveness.

Step 3: Prototyping and Testing

We produce prototypes of the custom cable assembly for design and functionality verification, so that the mass production can be satisfying. The prototyping process involves:

- Assembly of sample units based on high-precision methods

- Performance testing, such as continuity, insulation resistance, and durability testing

- The analysis of feedback and required design changes

Thanks to a dependable rapid prototype facility, we ensure to minimize the time-to-market while ensuring the reliability of our products.

Step 4: Sourcing High-Quality Materials

For a high-performing product, we obtain only the best-quality materials, which are as follows:

- Choosing copper conductors, insulation materials, and shielding from high-grade materials

- Ensuring all the connectors and terminals are up to industry standards

- Ensuring all the materials possess proper certifications to ensure compliance with international regulations

Thus, we also maintain the integrity and service life of our Custom Cable Assembly in Vietnam through high-quality procurement of materials.

Step 5: Manufacturing and Assembly

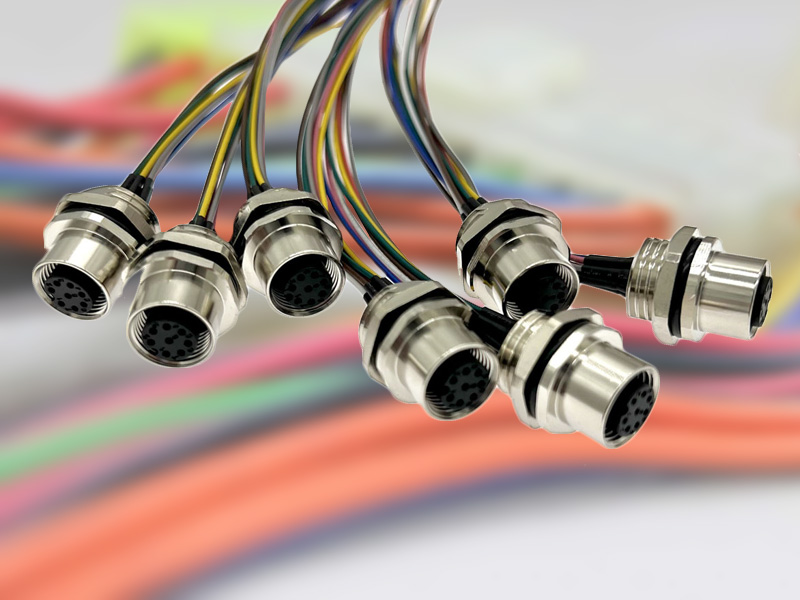

Having had the design proved and materials sourced, we had our Custom Cable Assembly manufactured here at our 3000-sq m Vietnamese factory. Our current manufacturing process involves:

- Wiring cutting and stripping using very specialized equipment

- Automated and semi-automated crimping, soldering, and connector assembly machinery

- Overmolding and insulating for greater durability and resistance to the elements

With a blend of automation and skilled labor, we have achieved efficiency, precision, and consistency in each custom-assembled cable assembly we produce.

Step 6: Stringent Quality Control and Testing

Quality is our top priority; each Custom Cable Assembly made in Vietnam undergoes stringent testing, including:

- Electrical testing (continuity, resistance, and high-voltage testing)

- Mechanical testing (pull strength, flexibility, and durability tests)

- Environmental testing (temperature, humidity, and vibration resistance)

Our ISO 9001-certified quality control system guarantees that all of our products perform to the highest standards of the industry to be established before our customers receive them.

Step 7: Customization of Packaging and Delivery

Upon meeting all the quality standards, SINNHONG ELECTRONICS custom cable assemblies will be equipped with:

- Packaging and labeling as per customer requirements

- Safe and secure transportation services delivered to the customers ahead of time specified

- Ability to ship by any of the flexible options ideal for international delivery

Our Custom Cable Assembly in Vietnam shipping is complete with traceability and documentation, ensuring total customer satisfaction.

Why SINNHONG ELECTRONICS for Custom Cable Assembly in Vietnam?

There are numerous reasons we stand out as a top-notch Custom Cable Assembly Provider in Vietnam:

- Customization Expertise

Our engineering staff offers tailored solutions in almost all sectors, from automotive to industrial machinery, telecommunications, and consumer electronics.

- State-of-the-Art Manufacturing

The Vietnamese facility is equipped with automation and semi-automation technologies of the best quality, which ensures high accuracy, efficiency, and consistency of every product.

- Cost-Effective Solutions

By assembling Custom Cable Assembly in Vietnam, we can compete fiercely on price and maintain the highest quality. Bulk purchase has provided us with the negotiating power to reduce the pricing and share the advantages with our clients.

- Rapid Turnaround Time

Fast prototyping and lean manufacturing enable us to produce and ship custom cable assemblies at fast speed, thereby reducing the time-to-market for our customers.

- Strict Quality Control

Every custom cable assembly is put through rigorous testing to ensure it meets international quality standards due to our ISO 9001 certification.

- Flexible Manufacturing

Flexible in design, materials, and configuration to be able to accommodate the different needs of the customers for both simple to complex custom cable assembly.

- Global Reach with Local Benefit

Custom Cable Assembly in Vietnam becomes much more reasonable and accessible to the international market because our operation in Vietnam avoids high tariffs and lower labor costs.

- Customer-Centric

From customer service to on-time delivery and technical support, we have a customer-centric policy throughout each step of the project.

We adopt a systematic strategy for the completion of any project from start to finish.

Leave a Reply