High-Density Polyethylene (HDPE) sheets have become a crucial material in the world of custom fabrication. Known for their versatility, durability, and cost-effectiveness, High Density Polyethylene Sheets offer numerous advantages that make them an ideal choice for a wide range of applications. Whether used in industrial settings, commercial structures, or personal projects, HDPE sheets provide unmatched performance in both functional and aesthetic aspects. This article explores the benefits of using HDPE sheets in custom fabrication and why they are highly sought after by manufacturers and fabricators alike.

Understanding HDPE Sheets

HDPE (High-Density Polyethylene) is a type of thermoplastic polymer made from petroleum. This plastic material is known for its high strength-to-density ratio, making it one of the most durable materials available for fabrication. HDPE sheets are produced in large panels and can be cut, welded, and molded into various shapes and sizes to meet specific requirements in different industries.

In custom fabrication, HDPE sheets are frequently used to create tailored components such as panels, signs, containers, and more. The flexibility and adaptability of HDPE make it a go-to material for manufacturers who require precision and reliability in their products.

Advantages of HDPE Sheets in Custom Fabrication

Exceptional Durability and Strength

One of the primary reasons HDPE sheets are favored in custom fabrication is their exceptional strength. HDPE is a robust material that can withstand heavy loads, impacts, and wear over time. This makes it highly suitable for creating products that require long-lasting durability, such as industrial parts, storage containers, and outdoor applications.

HDPE sheets are also resistant to abrasions, dents, and scratches, maintaining their appearance and functionality even after prolonged use. This durability is particularly important in environments where materials are exposed to harsh conditions, such as construction sites, factories, and outdoor installations.

Resistance to Chemicals and Corrosion

HDPE is chemically inert, meaning it does not react with most substances, including acids, bases, oils, and solvents. This chemical resistance makes HDPE sheets ideal for use in industries where contact with aggressive chemicals or substances is common, such as in the manufacturing of chemical tanks, pipes, and trays.

Furthermore, HDPE does not corrode like metals, which is particularly important in industries that deal with corrosive environments such as the food, medical, and automotive industries. Its resistance to corrosion ensures that products fabricated from HDPE retain their structural integrity over time.

Lightweight and Easy to Handle

Despite its strength, HDPE is lightweight, making it easier to handle, transport, and install. For fabricators, this ease of handling reduces labor costs and time. Custom fabrication projects that require cutting, shaping, or installation can be completed with minimal effort, thanks to the lightweight nature of HDPE sheets.

Moreover, the ease with which HDPE sheets can be cut and shaped ensures that they can be adapted to meet precise specifications. Whether fabricating a unique design or a complex component, HDPE sheets are user-friendly and easy to work with.

Weather and UV Resistance

Another significant benefit of HDPE sheets is their resistance to weathering and ultraviolet (UV) radiation. HDPE sheets are naturally resistant to UV rays, which prevents them from degrading or losing their strength when exposed to sunlight for long periods. This makes HDPE sheets ideal for outdoor applications, such as signage, fencing, and protective covers.

In regions with extreme weather conditions, HDPE sheets can withstand the effects of harsh sun, rain, snow, and wind without deteriorating. This resistance to weathering ensures that products fabricated from HDPE continue to perform reliably in outdoor environments.

Low Maintenance Requirements

HDPE sheets are incredibly easy to maintain. Their smooth surface resists the accumulation of dirt, grime, and bacteria, making them a preferred choice in food processing and medical applications where hygiene is critical. Cleaning HDPE surfaces typically requires nothing more than a mild detergent and water, reducing maintenance costs and time for manufacturers.

In addition, HDPE sheets are non-porous, which helps prevent the growth of mold, mildew, and other microorganisms. This is particularly important for applications in industries that require sanitary conditions, such as healthcare and food production.

Cost-Effective Solution

In comparison to other materials like metals, HDPE is a more affordable option for custom fabrication projects. The lower raw material cost, combined with the ease of fabrication and low maintenance requirements, makes HDPE sheets a cost-effective solution for manufacturers, reducing overall production costs.

For fabricators who need to create large quantities of parts or components, HDPE sheets offer significant savings without compromising quality or performance. This affordability makes HDPE sheets an attractive alternative for businesses looking to optimize their production processes while maintaining a high standard of quality.

Environmental Friendliness

HDPE is recyclable, making it an environmentally friendly option for custom fabrication. After its useful life, HDPE sheets can be recycled and reused in various applications, reducing waste and the environmental impact associated with disposal. This is especially important for businesses committed to sustainable practices and reducing their carbon footprint.

Furthermore, the production process for HDPE sheets is less energy-intensive than for many other materials, making it a greener choice overall.

Versatility in Design and Applications

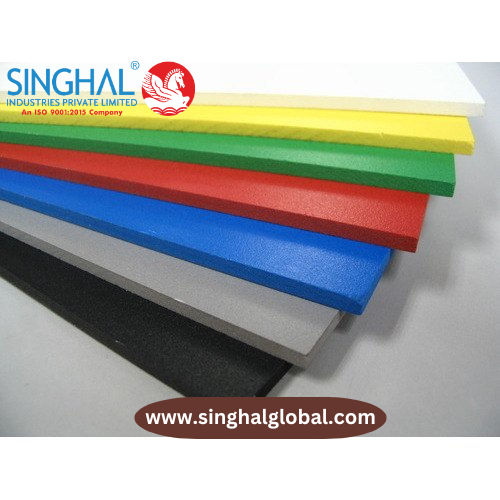

One of the most significant benefits of HDPE sheets in custom fabrication is their versatility. Available in a variety of thicknesses, sizes, and colors, HDPE sheets can be used for a wide range of applications, from structural components to decorative finishes.

HDPE sheets can be easily cut, drilled, welded, and thermoformed to create components that meet the exact specifications required. This adaptability allows fabricators to create everything from simple panels to complex and intricate designs, ensuring that the final product meets all functional and aesthetic requirements.

Why Choose HDPE Sheets from Suppliers in Ahmedabad?

When looking for HDPE sheets for custom fabrication, it is essential to source them from reliable suppliers. HDPE sheets 4×8 suppliers in Ahmedabad are known for offering high-quality products that meet industry standards and specifications. Suppliers in Ahmedabad provide a diverse range of HDPE sheets in various grades, thicknesses, and finishes, allowing businesses to select the best material for their fabrication needs.

Choosing a reputable HDPE manufacturer in Ahmedabad ensures that the products are made with precision and quality in mind. Whether you are working on a small-scale project or a large industrial order, sourcing HDPE sheets from trusted suppliers guarantees that you are receiving a top-grade product that will perform reliably for years to come.

Conclusion

In conclusion, HDPE sheets offer numerous advantages for custom fabrication projects, ranging from their strength and durability to their environmental benefits. When sourced from reliable suppliers, HDPE sheets provide a cost-effective, versatile, and long-lasting solution for various industries and applications.

Frequently Asked Questions (FAQs)

What are the different grades of HDPE sheets available?

HDPE sheets come in various grades, including standard, FDA-approved, and UV-resistant grades. The specific grade of HDPE you choose will depend on the requirements of your project, such as the need for chemical resistance, food-grade certification, or outdoor durability.

Can HDPE sheets be welded together for custom fabrication?

Yes, HDPE sheets can be welded using specialized equipment and techniques, such as butt welding or extrusion welding. This makes it possible to create larger structures or seamless parts from multiple sheets, offering flexibility in custom fabrication.

Are HDPE sheets suitable for outdoor applications?

Yes, HDPE sheets are highly resistant to UV radiation and weathering, making them ideal for outdoor applications. They maintain their strength and appearance even when exposed to harsh sunlight, rain, and extreme weather conditions.

Leave a Reply