In today’s rapidly evolving industrial landscape, materials that combine durability, flexibility, and cost-effectiveness are in high demand. Among these, corrugated PP sheets have emerged as a standout solution, offering a blend of superior performance and adaptability across various sectors. This article delves into the intricacies of corrugated PP sheets, exploring their composition, benefits, and diverse applications, while also addressing common queries to provide a comprehensive understanding of this remarkable material.

Understanding Corrugated PP Sheets

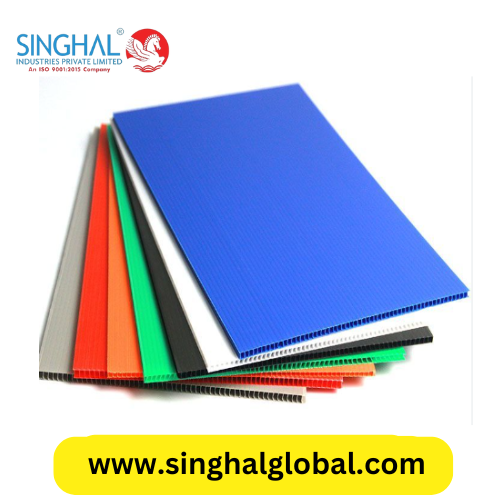

Corrugated PP sheets, or corrugated polypropylene sheets, are engineered from polypropylene, a versatile thermoplastic polymer known for its robustness and lightweight nature. The corrugated structure of these sheets enhances their strength and rigidity, making them suitable for applications that require both flexibility and durability. Unlike traditional materials, Corrugated PP sheets are resistant to moisture, chemicals, and UV radiation, ensuring longevity even in harsh environments.

Polypropylene Corrugated Sheets: Composition and Manufacturing

Polypropylene corrugated sheets are manufactured through a process that involves melting polypropylene pellets and extruding them into continuous sheets with a corrugated pattern. This corrugation not only provides structural integrity but also reduces material usage, making it an economically viable option. The manufacturing process allows for customization in terms of thickness, color, and corrugation size, catering to specific industry requirements. The inherent properties of Polypropylene corrugated sheet such as high tensile strength and resistance to fatigue, make these sheets a preferred choice for various engineering and construction applications.

Advantages of Corrugated PP Sheets

One of the primary advantages of Corrugated PP sheet is their exceptional strength-to-weight ratio. This makes them ideal for applications where reducing weight without compromising on strength is crucial. Additionally, their resistance to impact and abrasion ensures that they maintain their integrity even under strenuous conditions. The lightweight nature of corrugated PP sheets facilitates easier handling and installation, reducing labor costs and time. Furthermore, their recyclability aligns with sustainable practices, offering an eco-friendly alternative to conventional materials.

Applications Across Industries

Corrugated PP sheets find extensive use across a multitude of industries. In the construction sector, they are employed for roofing, wall panels, and flooring solutions, where their moisture-resistant properties prevent structural damage. The packaging industry benefits from their lightweight yet sturdy nature, using them for protective packaging and display stands. In the automotive sector, these sheets are utilized in interior components, providing both aesthetic appeal and functional durability. Additionally, the agricultural industry leverages corrugated PP sheets for greenhouse covers and irrigation systems, where their resistance to environmental stressors is invaluable.

Customization and Design Flexibility

The design flexibility of corrugated PP sheets allows for extensive customization to meet specific project needs. Manufacturers can tailor the corrugation pattern, thickness, and surface finish to suit particular applications. This adaptability is particularly beneficial in creative industries, where unique designs and structural requirements are often necessary. Moreover, the ability to produce these sheets in various colors and finishes enhances their aesthetic appeal, making them suitable for both functional and decorative purposes.

Economic Benefits and Cost Efficiency

From an economic standpoint, corrugated PP sheets offer significant cost benefits. Their lightweight nature reduces transportation and installation costs, while their durability minimizes the need for frequent replacements. The efficient manufacturing process ensures that production costs remain low, making these sheets an affordable option for large-scale projects. Additionally, their recyclable properties contribute to long-term cost savings, as materials can be repurposed rather than discarded.

Environmental Sustainability

In an era where sustainability is paramount, corrugated PP sheets stand out as an environmentally friendly choice. Polypropylene is a recyclable material, and the corrugated structure often requires less plastic to achieve the desired strength, reducing overall material usage. The longevity of these sheets means fewer replacements and less waste, further contributing to environmental conservation. Moreover, their resistance to degradation by UV rays and chemicals ensures that they do not release harmful substances into the environment over time.

Maintenance and Longevity

Maintaining corrugated PP sheets is relatively straightforward, contributing to their appeal across various industries. Their resistance to moisture, chemicals, and UV radiation means that they do not require extensive maintenance to preserve their functionality and appearance. Regular cleaning with mild detergents is typically sufficient to keep them in optimal condition. The inherent durability of these sheets ensures a long service life, making them a reliable investment for both commercial and residential applications.

Innovations and Future Prospects

The field of materials science continues to evolve, and corrugated PP sheets are at the forefront of several innovative developments. Advances in polymer technology have led to the creation of more resilient and versatile polypropylene variants, enhancing the performance of corrugated PP sheets. Additionally, the integration of smart technologies, such as sensors and conductive materials, is opening new avenues for their use in smart infrastructure and IoT applications. As industries seek more efficient and sustainable materials, the future prospects for corrugated PP sheets remain promising.

Conclusion

Corrugated PP sheets represent a harmonious blend of strength, versatility, and economic efficiency, making them a preferred choice across diverse industries. Their robust construction, combined with the inherent benefits of polypropylene, ensures that they meet the demands of modern applications while adhering to sustainable practices. As technological advancements continue to enhance their properties and expand their applications, corrugated PP sheets are poised to play a pivotal role in shaping the future of material engineering and industrial design.

Frequently Asked Questions

1.What are the key advantages of using corrugated pp sheets in construction?

Corrugated pp sheets offer several advantages in construction, including their lightweight yet strong structure, which reduces transportation and installation costs.

2. How does a polypropylene corrugated sheet differ from other types of corrugated materials?

Polypropylene corrugated sheets differ from other corrugated materials primarily in their composition and properties. Polypropylene is a thermoplastic polymer known for its high tensile strength, flexibility,

3. Where can corrugated pp sheets be effectively utilized outside of construction?Beyond construction, corrugated pp sheets are effectively utilized in various industries such as packaging, automotive, agriculture, and retail. In packaging,

Leave a Reply