If you work in an industry that deals with bulk materials like grains, fertilizers, cement, or chemicals, you know how important packaging efficiency is. Manually filling large bags is not just time-consuming—it also leads to inconsistencies, material waste, and high labor costs. That’s where a bulk bagger comes in.

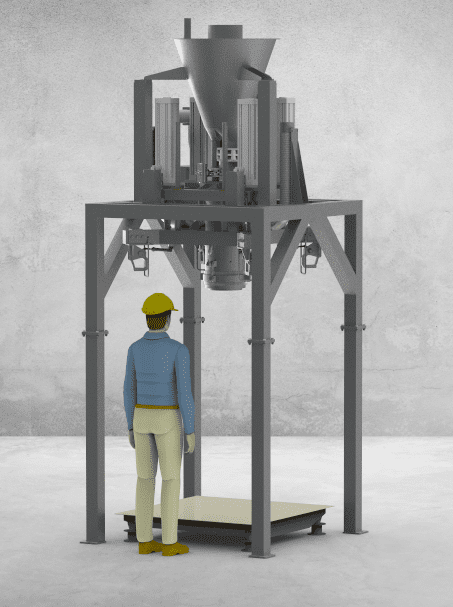

A bulk bagger is a machine designed to automate and streamline the process of filling large bags, commonly known as bulk bags or FIBCs (Flexible Intermediate Bulk Containers). These machines ensure precise filling, reduce labor efforts, and improve overall productivity. But how exactly do they work, and why should businesses invest in them? Let’s dive into the benefits and working mechanism of a bulk bagger to understand its significance in modern industrial operations.

What Is a Bulk Bagger?

A bulk bagger is a specialized piece of equipment used to fill large bags with dry, flowable materials like powders, granules, and small-sized solids. These machines ensure that each bag is filled accurately and securely, making storage and transportation easier and more efficient.

Instead of relying on manual labor to scoop and weigh materials, a bulk bagger automates the process, allowing businesses to achieve consistent weight measurements while minimizing product loss and packaging time.

How Does a Bulk Bagger Work?

The operation of a bulk bagger is straightforward and highly efficient. Here’s a step-by-step breakdown of how it works:

- Bag Positioning – The empty bulk bag is placed on the machine and securely attached to the filling spout. Some machines come with automatic bag placement features, while others require manual attachment.

- Inflation (Optional Feature) – Some bulk baggers include a bag inflation system that expands the bag before filling. This helps maintain the bag’s shape and ensures uniform filling.

- Material Dispensing and Weighing – The bulk material is dispensed into the bag through a controlled feeding system. A built-in weighing mechanism ensures that the correct amount of material is loaded, preventing overfilling or underfilling.

- Compaction and Settling – To maximize storage efficiency, some machines feature vibration or air-settling systems that help compact the material inside the bag. This improves stability during transportation.

- Sealing and Bag Release – Once the bag reaches the target weight, it is sealed (manually or automatically) and then released from the machine for storage or shipment.

This automated process minimizes human error, increases speed, and ensures consistency in every bag filled.

Why Should Your Business Invest in a Bulk Bagger?

If you’re still on the fence about whether a bulk bagger is a worthy investment, consider these key benefits:

1. Increased Efficiency and Speed

Manual bag filling is slow and requires significant manpower. A bulk bagger dramatically speeds up the process, allowing businesses to package more material in less time. This is especially beneficial for companies with high production demands.

2. Precise Weight Measurement

Overfilling bags leads to material wastage and higher costs, while underfilling can result in non-compliance with industry regulations. A bulk bagger eliminates these issues with its precise weighing system, ensuring accuracy in every package.

3. Reduced Labor Costs

Automating the bagging process means fewer workers are needed for packaging operations. This reduces labor expenses and allows employees to focus on other essential tasks, improving overall productivity.

4. Improved Workplace Safety

Lifting and handling heavy bags manually can lead to workplace injuries, including back strains and muscle fatigue. A bulk bagger reduces the need for physical labor, creating a safer work environment and lowering the risk of accidents.

5. Consistent and High-Quality Packaging

For businesses that ship products locally and internationally, maintaining consistency in packaging is crucial. A bulk bagger ensures that every bag is filled with the exact same amount of material, eliminating discrepancies and ensuring professional-quality packaging.

Choosing the Right Bulk Bagger for Your Business

Not all bulk baggers are the same. Choosing the right machine depends on several factors, including the type of material being packaged, required production speed, and desired level of automation. Here are some key considerations:

1. Type of Material

The properties of the material being packaged determine the type of bulk bagger you need. Powders may require dust-tight filling systems, while granular or coarse materials may need vibration-assisted filling to prevent clogging.

2. Weighing Accuracy

Choose a bulk bagger with a high-precision weighing system to ensure every bag is filled accurately. This prevents material waste and ensures compliance with industry standards.

3. Level of Automation

Some machines are fully automatic, requiring minimal human involvement, while others are semi-automatic and need an operator to assist with bag placement. Consider your production volume and budget when selecting between these options.

4. Durability and Build Quality

Since bulk baggers handle heavy loads daily, durability is crucial. Machines made of high-quality stainless steel are ideal for withstanding constant use while minimizing maintenance requirements.

5. Maintenance and Technical Support

Regular maintenance keeps machines running smoothly. Choose a bulk bagger from a manufacturer that offers easy access to spare parts and reliable customer support to reduce downtime.

Industries That Benefit from a Bulk Bagger

A bulk bagger is a versatile machine used across various industries. Some of the key sectors that benefit from these machines include:

- Agriculture – Used for packaging grains, seeds, and animal feed.

- Construction – Ideal for handling cement, sand, and other building materials.

- Chemical Industry – Essential for packaging powders, granules, and chemical compounds.

- Food Industry – Used for bulk packaging of flour, sugar, and other dry food products.

- Mining and Minerals – Helps in efficient packaging of ores and minerals for transport.

The Future of Bulk Bagging Technology

As industries continue to evolve, so does packaging technology. Modern bulk baggers are incorporating smart automation, IoT (Internet of Things) connectivity, and AI-based monitoring systems. These advancements allow real-time tracking, remote adjustments, and predictive maintenance, reducing downtime and improving efficiency.

Additionally, sustainability is becoming a priority in industrial packaging. Many manufacturers are developing energy-efficient bulk baggers that reduce material waste and contribute to eco-friendly packaging solutions.

Final Thoughts

A bulk bagger is more than just a packaging machine—it’s a game-changer for businesses that handle bulk materials. From improving efficiency and reducing labor costs to ensuring precise weight measurement and workplace safety, the benefits of investing in a bulk bagger are undeniable.

If your business deals with bulk packaging and you’re looking for ways to optimize your process, now is the time to consider a bulk bagger. It’s a smart investment that not only enhances productivity but also provides long-term cost savings and operational improvements.

Would you like to explore how a bulk bagger can make a difference in your industry? Let us know how it could benefit your business!

Leave a Reply