Electric switches, plugs, and sockets are fundamental components of electrical infrastructure, facilitating power distribution and connection in residential, commercial, and industrial setups. These devices are essential for ensuring safe and efficient operation of electrical systems. With rapid urbanisation, infrastructure development, and growing demand for smart home solutions, the market for high-quality and innovative electric switches, plugs, and sockets has expanded significantly. Setting up a manufacturing plant for Electric Switches, Plugs, and Sockets requires strategic planning, advanced production techniques, and adherence to stringent safety standards to meet diverse market needs.

Overview of Electric Switches, Plugs, and Sockets

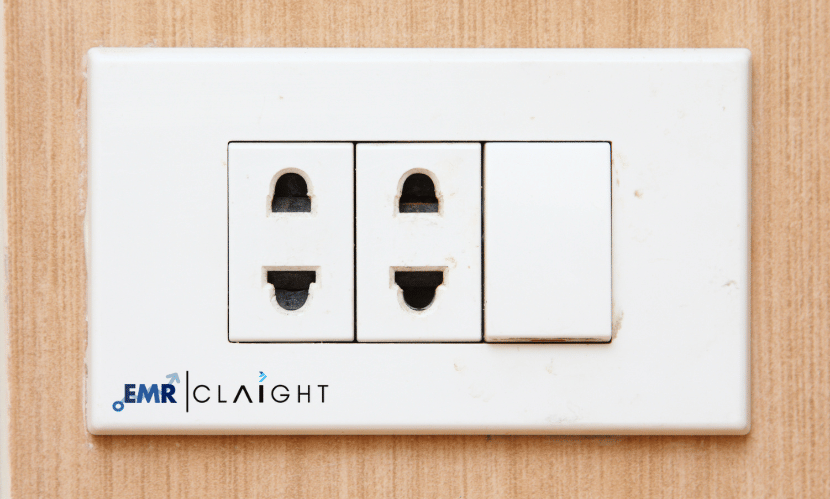

Electric switches, plugs, and sockets are designed to enable seamless connectivity and control within electrical systems.

- Switches: Allow users to control the flow of electricity to appliances and devices.

- Plugs: Provide a safe and portable means of connecting appliances to power sources.

- Sockets: Serve as fixed connection points for supplying power to electrical devices.

Modern products often incorporate smart features, enhanced safety mechanisms, and stylish designs to meet consumer preferences.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/electric-switches-plugs-sockets-manufacturing-plant-project-report/requestsample

Key Considerations for Setting Up the Manufacturing Plant

Establishing a manufacturing plant for electric switches, plugs, and sockets involves multiple steps, from site selection to compliance with regulatory standards.

1. Location and Site Selection

Choosing an appropriate location is critical to operational success. Key factors include:

- Proximity to suppliers of raw materials such as plastics, metals, and electrical components.

- Availability of skilled labour for manufacturing and assembly.

- Access to transportation networks for raw material delivery and product distribution.

The site should also provide sufficient space for production facilities, storage, and administrative operations.

2. Raw Materials and Procurement

High-quality raw materials are essential for producing durable and safe electrical components. These include:

- Plastics: Used for insulation and casing, including PVC or polycarbonate.

- Metals: Such as copper and brass for electrical contacts and terminals.

- Screws and Fasteners: For securing components within devices.

- Conductors: High-quality wires and strips for optimal conductivity.

- Packaging Materials: For protecting products during transport and storage.

Establishing strong supplier relationships ensures consistent material availability and cost efficiency.

3. Manufacturing Process

The production of electric switches, plugs, and sockets involves several steps:

- Material Preparation: Cutting and shaping raw materials such as plastics and metals.

- Component Manufacturing: Producing internal parts like contacts, terminals, and switches.

- Assembly: Combining all components to form the final product.

- Quality Testing: Ensuring compliance with safety and performance standards.

- Packaging: Securing the finished products in durable, tamper-proof packaging.

4. Quality Control

Maintaining stringent quality standards is essential to produce reliable electrical products. Testing parameters include:

- Insulation resistance and dielectric strength.

- Contact performance and durability under load.

- Mechanical integrity of switches and sockets.

Regular testing ensures compliance with international safety standards and enhances consumer trust.

5. Regulatory Compliance

Adherence to electrical safety and environmental regulations is mandatory. This includes:

- Proper labelling with specifications, safety warnings, and certifications.

- Compliance with ISO, CE, or BIS standards, depending on the target market.

- Implementation of environmentally sustainable production practices.

Equipment and Technology

Setting up a manufacturing plant for electric switches, plugs, and sockets requires advanced equipment to ensure precision and efficiency. Key equipment includes:

- Injection Moulding Machines: For producing plastic components.

- Metal Stamping Machines: To create contacts and other metallic parts.

- Assembly Lines: For efficient assembly of components.

- Testing Equipment: To verify electrical and mechanical performance.

- Packaging Machines: For secure and tamper-proof packing.

Automation technologies can improve production efficiency, reduce waste, and maintain consistent quality.

Workforce and Training

A skilled workforce is essential for efficient plant operations. Key roles include assembly technicians, quality assurance personnel, and maintenance staff. Regular training programs ensure employees stay updated on manufacturing techniques, safety protocols, and regulatory compliance.

Packaging and Distribution

Proper packaging is crucial to maintain the quality and safety of electric switches, plugs, and sockets. Packaging options include individual boxes, bulk cartons, or customised solutions for specific markets. Efficient logistics networks ensure timely delivery to distributors, retailers, and wholesalers.

Environmental and Safety Aspects

Sustainability and safety are integral to the production process. Measures include:

- Waste Management: Recycling scrap materials and minimising production waste.

- Energy Efficiency: Using energy-efficient machinery to reduce the plant’s carbon footprint.

- Worker Safety: Providing protective gear and regular training to minimise risks.

Market Applications and Trends

Electric switches, plugs, and sockets are used across diverse industries and applications:

- Residential: For lighting, appliances, and smart home systems.

- Commercial: In offices, retail spaces, and public infrastructure.

- Industrial: For machinery, tools, and heavy-duty applications.

- Hospitality and Healthcare: Ensuring safe and reliable power connections.

Emerging trends include:

- Smart Switches and Sockets: Enabled with Wi-Fi or Bluetooth for remote control and automation.

- Aesthetic Designs: Offering stylish and customisable options for modern interiors.

- Sustainable Materials: Incorporating eco-friendly materials to reduce environmental impact.

Challenges in Manufacturing

Manufacturers face challenges such as maintaining consistent product quality, managing raw material costs, and adhering to stringent regulatory standards. Addressing these challenges involves:

- Investing in advanced production technologies and quality control systems.

- Developing sustainable practices for waste and energy management.

- Building strong supplier relationships for reliable sourcing of raw materials.

By focusing on these critical aspects, businesses can establish a successful manufacturing plant for electric switches, plugs, and sockets, meeting the growing demand for innovative and reliable electrical solutions in a competitive market.

Leave a Reply