In today’s world, sustainable practices are no longer optional but essential. Businesses and consumers alike are gravitating towards eco-friendly alternatives in every facet of their lives. Packaging, a significant contributor to waste, has become a primary focus for sustainability. Paper pulp molding, a versatile and environmentally friendly material, is a game-changer in the realm of eco-conscious packaging. This article delves into innovative packaging ideas using paper pulp molding, showcasing its potential to reduce environmental impact while maintaining functionality and aesthetic appeal.

Understanding the Basics of Paper Pulp Molding

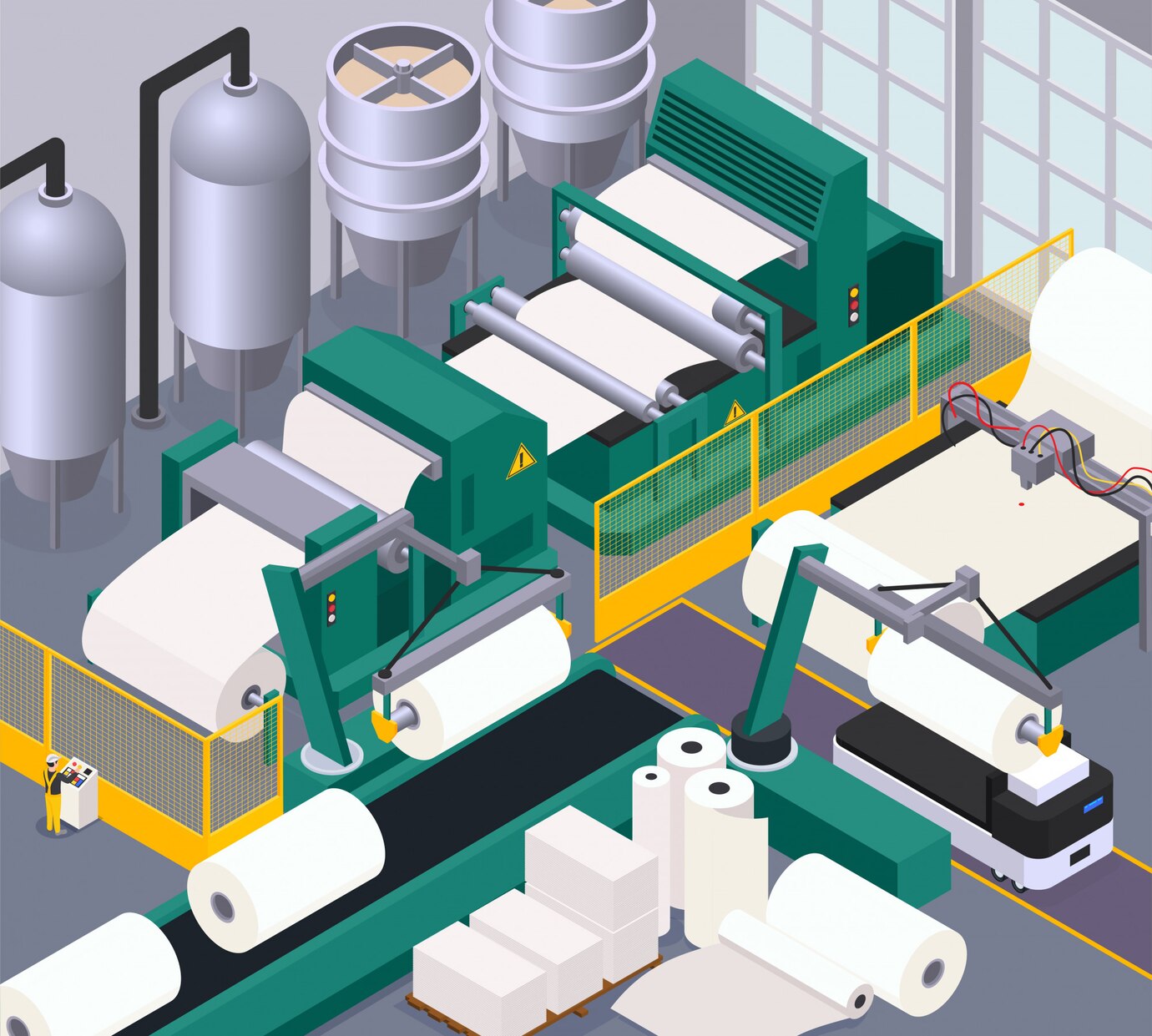

Paper pulp molding involves the transformation of recycled paper fibers into robust and biodegradable packaging products. The process typically starts with pulping waste paper, which is then shaped using molds into various forms. This method is not only eco-friendly but also cost-effective, leveraging recycled materials and requiring minimal energy consumption compared to other manufacturing methods.

The growing appeal of paper pulp molding lies in its adaptability. Businesses can design customized packaging to fit specific products, ensuring safety, durability, and a unique customer experience. Whether for protective packaging, food containers, or decorative boxes, the possibilities with paper pulp molding are extensive, making it a sustainable choice for diverse industries.

Protective Packaging Solutions with Paper Pulp Molding

Protective packaging, traditionally reliant on plastic and styrofoam, is undergoing a green revolution with paper pulp molding. This material is ideal for creating packaging inserts that secure fragile items such as electronics, glassware, and medical equipment. Its ability to cushion and protect while remaining lightweight gives it an edge over conventional alternatives.

Moreover, the biodegradability of molded pulp ensures that end-of-life disposal has minimal environmental impact. Companies like Apple have already incorporated molded pulp for packaging their products, setting a precedent for sustainable practices in technology. By using molded pulp, businesses can not only meet consumer demand for sustainability but also enhance their brand image as environmentally conscious leaders.

Innovative Food Packaging with Molded Pulp

The food industry is another sector embracing the benefits of molded pulp. Paper pulp molding is widely used for producing biodegradable trays, plates, cups, and containers. These products are free of harmful chemicals, making them safe for food contact, while their compostable nature aligns with efforts to reduce single-use plastics.

An added advantage is the customizability of molded pulp to meet various requirements such as thermal insulation and liquid resistance. Coffee cups with molded pulp lids, egg cartons, and takeaway food containers are prime examples of how this technology is reshaping food packaging. Restaurants and cafes can use these solutions to demonstrate their commitment to sustainability, appealing to eco-conscious diners.

Creative Branding Opportunities with Molded Pulp Packaging

Beyond functionality, molded pulp packaging offers exceptional opportunities for branding and aesthetic appeal. With advancements in design and manufacturing techniques, businesses can create unique packaging that reflects their brand identity. Embossed logos, intricate patterns, and color customization are just a few possibilities with paper pulp molding.

This packaging method is particularly popular in premium markets, where the combination of sustainability and sophistication is highly valued. Luxury goods and artisanal products packaged in molded pulp boxes not only stand out on the shelves but also convey a powerful message of environmental responsibility. The tactile and visual appeal of such packaging enhances the overall customer experience, turning it into a memorable interaction.

Future Prospects and Challenges in Paper Pulp Molding

The future of paper pulp molding looks promising, driven by increasing environmental awareness and technological advancements. Innovations such as water-resistant coatings and improved molding techniques are expanding the scope of applications for molded pulp packaging. As regulations against single-use plastics tighten globally, the demand for eco-friendly packaging alternatives will likely surge.

However, challenges remain. The high initial costs of setting up molding equipment and the limited scalability of production can be barriers for smaller businesses. Additionally, while molded pulp is biodegradable, ensuring the availability of proper composting facilities is crucial for its effective disposal. Addressing these hurdles through collaboration and investment will be key to unlocking the full potential of paper pulp molding.

Conclusion

Eco-friendly packaging ideas using paper pulp molding represent a significant leap towards a sustainable future. This innovative material offers a practical, customizable, and environmentally sound solution for various industries, from technology to food and luxury goods. By embracing paper pulp molding, businesses can reduce their environmental footprint while meeting consumer expectations for green practices. As the industry evolves, the synergy between sustainability and innovation promises a new era of packaging that benefits both the planet and its inhabitants.

Leave a Reply