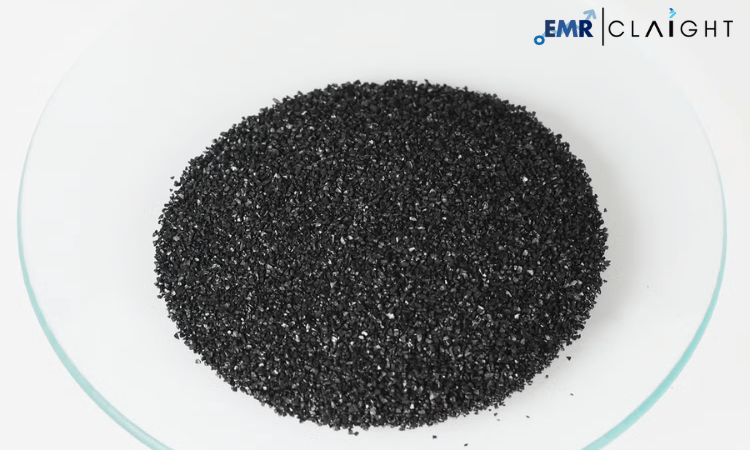

Acid washed granulated activated carbon (GAC) is a highly refined material extensively used in various industries, including water purification, air filtration, and chemical processing. Its enhanced adsorption properties and high purity make it a preferred choice for critical applications. Establishing an acid washed granulated activated carbon manufacturing plant provides an opportunity to cater to the increasing demand for premium-quality activated carbon in both domestic and international markets. This report highlights the essential components, production processes, and operational requirements for setting up such a facility.

Overview of Acid Washed Granulated Activated Carbon Production

The production of acid washed granulated activated carbon involves treating raw carbon material, such as coconut shells or coal, with acids to remove impurities and enhance its adsorption properties. The acid washing process ensures that the final product meets stringent quality standards for use in sensitive applications like drinking water treatment and pharmaceutical manufacturing. Modern manufacturing practices focus on achieving uniform granulation, high surface area, and low ash content, making GAC suitable for a wide range of industries.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/acid-washed-granulated-activated-carbon-manufacturing-plant-project-report/requestsample

Key Components of an Acid Washed Granulated Activated Carbon Manufacturing Plant

Setting up a state-of-the-art manufacturing plant for acid washed granulated activated carbon requires specialised equipment and infrastructure to ensure efficient production. Key components include:

-

Raw Material Storage:

- Facilities for storing raw carbon materials such as coconut shells or coal.

- Systems to protect raw materials from moisture and contamination.

-

Carbonisation Units:

- Equipment to convert raw materials into char through controlled heating processes.

- Systems to ensure consistent carbonisation for optimal quality.

-

Activation Chambers:

- Reactors for treating carbonised material with steam or chemicals to enhance porosity.

- Advanced control systems to maintain the desired activation parameters.

-

Acid Washing Systems:

- Units for treating activated carbon with acid solutions to remove impurities.

- Processes to neutralise the acid and rinse the carbon thoroughly.

-

Drying and Granulation Units:

- Machinery to dry the washed carbon and form it into uniform granules.

- Equipment to achieve the desired granule size and texture.

-

Quality Testing Laboratories:

- Facilities to analyse adsorption capacity, surface area, and purity.

- Advanced instruments to ensure compliance with industrial standards.

-

Packaging and Storage:

- Automated systems for packaging the granulated carbon in secure containers.

- Climate-controlled warehouses for storing finished products.

Step-by-Step Guide to Acid Washed Granulated Activated Carbon Manufacturing

-

Raw Material Procurement:

- Source high-quality raw carbon materials such as coconut shells, wood, or coal.

- Conduct quality checks to ensure the materials meet production standards.

-

Carbonisation:

- Heat the raw materials in a controlled environment to produce char.

- Ensure uniform carbonisation to maintain the structural integrity of the material.

-

Activation:

- Treat the carbonised material with steam or chemicals to create a porous structure.

- Optimise activation parameters to maximise adsorption capacity.

-

Acid Washing:

- Wash the activated carbon with acid solutions to remove impurities and ash content.

- Neutralise the acid and rinse the carbon thoroughly to meet quality standards.

-

Drying and Granulation:

- Dry the washed carbon using specialised equipment to achieve the desired moisture content.

- Granulate the material into uniform sizes suitable for industrial applications.

-

Quality Testing:

- Test the final product for adsorption capacity, surface area, and chemical purity.

- Conduct additional tests to ensure compliance with client specifications and industry standards.

-

Packaging and Distribution:

- Package the granulated activated carbon in airtight containers to preserve quality.

- Label the packaging with product details, safety instructions, and usage guidelines.

- Distribute the product to industries such as water treatment, air purification, and food processing.

Applications of Acid Washed Granulated Activated Carbon

Acid washed granulated activated carbon is a versatile material used across various industries for its superior adsorption properties. Key applications include:

-

Water Treatment:

- Used for removing contaminants, odours, and impurities from drinking water.

- Essential in industrial water purification processes.

-

Air Filtration:

- Employed in air purifiers and industrial ventilation systems to remove pollutants and volatile organic compounds (VOCs).

-

Food and Beverage Industry:

- Used for decolourisation and purification of food and beverage products.

- Ensures product safety and quality.

-

Pharmaceutical Industry:

- Acts as a purification agent in the production of drugs and medical formulations.

-

Chemical Processing:

- Used as a catalyst support and in separation processes within chemical plants.

Safety and Environmental Considerations

Operating an acid washed granulated activated carbon manufacturing plant involves adhering to safety and environmental guidelines to ensure sustainable practices. Key considerations include:

-

Worker Safety:

- Provide training on handling chemicals and operating machinery safely.

- Equip workers with personal protective equipment (PPE) such as gloves, goggles, and respirators.

-

Waste Management:

- Implement systems to treat and neutralise acidic waste from the washing process.

- Recycle or responsibly dispose of by-products to minimise environmental impact.

-

Emission Control:

- Install filtration systems to manage emissions from carbonisation and activation processes.

- Monitor air and water quality regularly to ensure compliance with environmental regulations.

-

Energy Efficiency:

- Use energy-efficient equipment to reduce operational costs and carbon footprint.

- Explore renewable energy sources for powering plant operations.

Operational Challenges

Establishing and managing an acid washed granulated activated carbon manufacturing plant involves addressing various challenges to ensure efficient production and competitiveness. These challenges include:

-

Raw Material Availability:

- Ensuring a consistent supply of high-quality raw carbon materials.

- Managing seasonal variations in raw material availability.

-

Technological Advancements:

- Keeping up with innovations in activation and washing technologies.

- Investing in R&D to enhance product quality and production efficiency.

-

Market Competition:

- Competing with established manufacturers in a niche market.

- Differentiating products through superior quality and customisation.

-

Regulatory Compliance:

- Navigating complex environmental and safety regulations.

- Maintaining certifications and conducting regular audits to ensure compliance.

Emerging Trends in Acid Washed Granulated Activated Carbon Manufacturing

The industry is evolving with advancements in technology and changing market demands. Key trends include:

-

Sustainable Practices:

- Adoption of eco-friendly production methods to minimise environmental impact.

- Utilisation of renewable raw materials for carbon production.

-

High-Performance Products:

- Increasing demand for activated carbon with enhanced adsorption capacities.

- Development of customised solutions for specific industrial applications.

-

Digital Integration:

- Leveraging data analytics and IoT for real-time monitoring and process optimisation.

- Automation of manufacturing processes to improve efficiency and reduce costs.

-

Global Market Expansion:

- Growing demand in emerging markets for water and air purification applications.

- Opportunities for export and collaboration with international industries.

Economic and Social Impact

Establishing an acid washed granulated activated carbon manufacturing plant contributes significantly to industrial growth and community development. Key benefits include:

-

Job Creation:

- Provides employment opportunities in production, quality control, and logistics.

-

Industrial Growth:

- Supports related industries such as water treatment, air purification, and chemical manufacturing.

-

Technological Advancement:

- Encourages innovation in carbon activation and purification techniques.

-

Sustainability Initiatives:

- Promotes responsible manufacturing practices and efficient resource utilisation.

By focusing on quality, innovation, and sustainability, manufacturers can meet the growing demand for acid washed granulated activated carbon while contributing to environmental preservation and economic progress.

Leave a Reply