Wastewater treatment depends heavily on Membrane Bioreactors due to their execution of biological treatment methods through membrane filtration. The best mbr membranes deliver efficient filtration capabilities along with separation functions that generate improved wastewater quality than standard treatment techniques.

A membrane operating as a filtration barrier selects purified water by blocking solid particles together with microorganisms. Round-the-clock wastewater treatment at reduced space requirements makes MBRs a preferred choice for urban and industrial wastewater collection sites. Quality MBR systems depend entirely on the membranes so it becomes essential to rely on a reliable MBR membrane manufacturer.

The Essential Attributes of Foremost MBR Membrane Manufacturing Companies

1. Innovative Membrane Technology

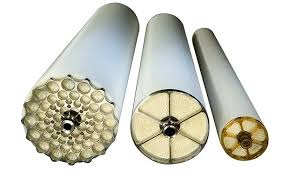

Technology leadership stands as the defining characteristic of the best mbr membranes manufacturing organizations. The manufacturers put significant funding into research to enhance membrane materials while designing new configurations along with improved structures. Different MBR membrane technologies utilize flat-sheet membranes at one extreme and tubular membranes as well as hollow fiber membranes at the other extreme.

The innovations incorporate features that optimize filtration ability while reducing membrane plugging and extending the membranes’ operational duration. Wastewater treatment plants face harsh operational conditions so manufacturers work to develop membranes that demonstrate enhanced mechanical strength and increased chemical resistance capacity.

2. Durability and Reliability

The durability of MBR membranes stands as a vital element for achieving extended performance in wastewater treatment facilities. Leading manufacturers build durable membranes that resist multiple operating stresses which maintain their functionality across diverse temperature ranges and study chemical exposures and high-pressure situations.

Extended membrane lifespan requires less maintenance and treatment plants operate with reduced downtime and decreased replacement costs. Quality control procedures performed by main manufacturers on their membranes meet demanding performance requirements to ensure a long operational lifespan across different environmental conditions.

3. Low Fouling Tendency

Fouling is the most critical challenge in the best mbr membranes technology because it causes a performance decline and enhances maintenance needs. The best membrane manufacturers are now focusing on membranes with low fouling tendencies. These membranes have been designed to minimize the attachment of microorganisms, organic matter, and other contaminants on the surface.

Surface modifications and hydrophilic coatings improve membrane anti-fouling properties. These membranes are easier to clean and maintain, reducing the chemical cleaning requirement and prolonging their service life.

4. Energy Efficiency

Energy consumption is another critical factor in the design of the best mbr membranes. Energy use is a huge factor in making a difference in the general running cost of a water treatment plant. Leading manufacturers need to design the membranes so that itheyuses less energy for filtration operations with high performance.

These membranes are optimized to lower TMP and, thus, reduce the energy demand for filtration processes. Manufacturers are also trying to reduce the energy consumed by pumps and motors of MBR plants through the use of membranes that exhibit lower fouling rates and higher permeability.

5. Customization options

The foremost benefit of best mbr membranes manufacturers is the possibility of customizing solutions based on specific requirements from customers. Not all wastewater treatment plants are the same, and manufacturers offer customization options to meet the specific needs of each facility.

Customizations may include changes in membrane size, porosity, and material composition, depending on the nature of the wastewater being treated. Custom solutions ensure that the MBR system is optimized for maximum efficiency and performance in each specific application, whether municipal, industrial, or commercial.

Advantages of Selecting Leading MBR Membrane Manufacturers

1. High-quality effluent

The primary aim of mbr membrane manufactures is to generate high-quality effluent that meets or exceeds all regulatory standards. Currently, the premier manufacturers of membranes produce products that generate the cleanest and safest effluent. These membranes are engineered to remove all contaminants, from suspended solids to bacteria, viruses, and organic matter, while still abiding by stringent environmental regulations. These membranes offer superior filtration capabilities to improve water reuse and resource recovery and thus form a core part of sustainable water management.

2. Cost-effectiveness

Though MBR membranes are slightly expensive at initial costs compared to the traditional filter-based methods, there is much more to their cost-effectiveness. The mbr membrane manufactures longer-lasting membranes with a lower intervention cost for maintenance, and since it is highly energy-efficient, it also boasts operating costs that pay off all those initial investment expenses over a long period.

3. Environmental Sustainability

A growing need for sustainable water treatment has caused MBR system uptake to increase significantly. Companies focusing on sustainability develop water membranes that reduce environmental harm. Membranes constructed from recyclable materials enable effective pollutant removal from water thus protecting natural water ecosystems. These systems support global water conservation through their capability to manage the reuse and recycling of processed water.

4. Global Reach and Local Support

Major mbr membrane manufactures & operates globally by offering wastewater treatment solutions for industrial plants throughout different worldwide areas. Their support services encompass all stages from installation through operational maintenance. Local engineering teams within manufacturer networks provide swift maintenance help equipment replacement services and diagnostic support which reduces system downtime for treatment plants. Primemtec’s manufacturer ensures that customer-operated MBR systems get dependable maintenance during the system lifespan.

Summary

For the best mbr membranes manufacturer selection it is crucial to examine technological capabilities while also evaluating durability alongside energy efficiency and support availability. Primemtec’s manufacturers excel at membrane production and deliver strong long-lasting membranes that enable outstanding filtering results along with economical operation over extended periods. Through their sustainability focus these manufacturers pioneer clean water solutions together with improved procedures for wastewater treatment.

FAQs

What measures exist to minimize membrane fouling?

The choice of low-fouling membrane materials alongside suitable maintenance practices allows operators to minimize fouling.

Are MBR membranes energy-efficient?

Leading MBR membrane manufacturers build products that incorporate energy-saving features that decrease power consumption when performing filtration tasks.

What capacity exists for MBR systems to process industrial wastewater?

MBR systems demonstrate exceptional ability to handle industrial wastewater by generating high-quality water that becomes available for reuse or discharge purposes.

Leave a Reply