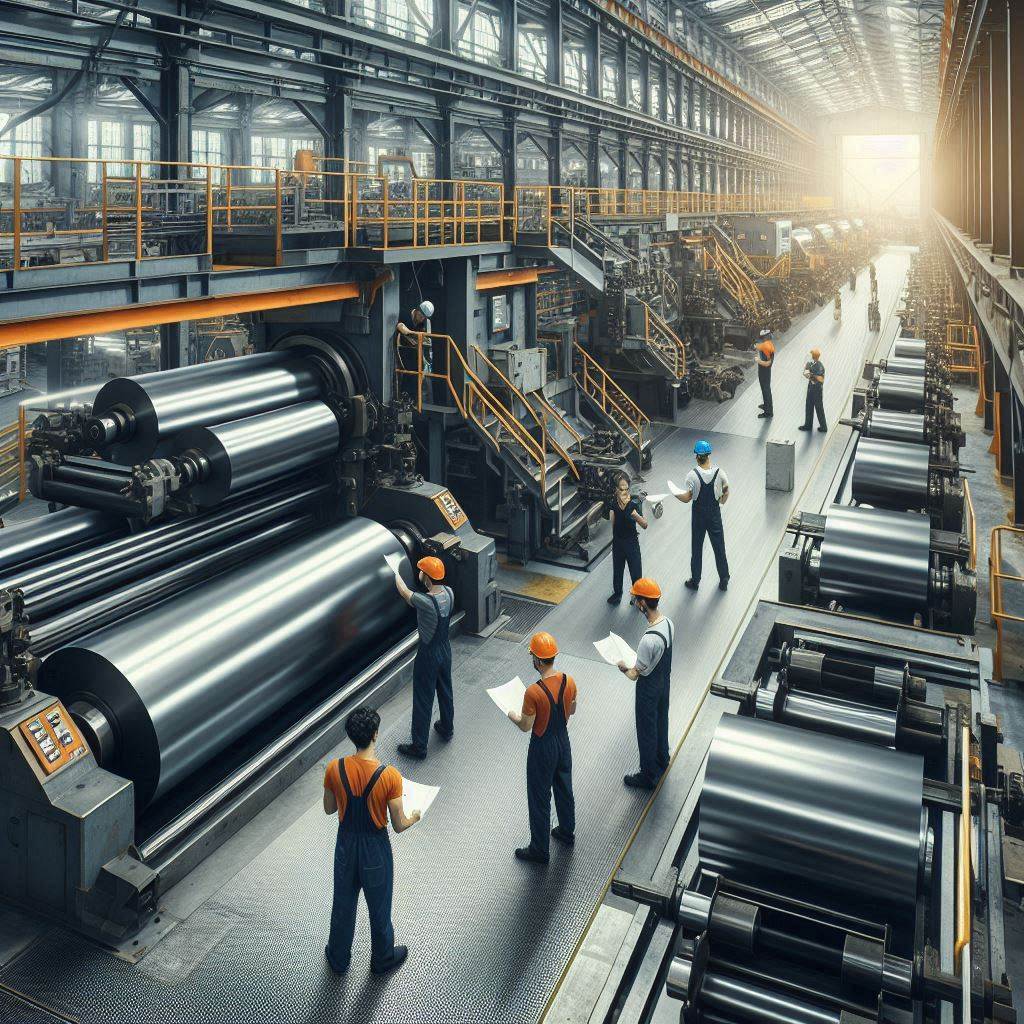

Metal rolling machines are used in many manufacturing industries and finds its applications in several industrial sectors including aerospace, defense, automobile and construction.

1. Three-Roll Plate Rolling Machines

The most widely used bending equipment in India, to bend metal sheets in cylindrical and curved shapes, is three-roll plate rolling machines. These machines provide three rollers arranged in a triangular configuration, in which the top roller downwardly press, while the bottom two rollers support and move the sheet through the rolling process. They are available in mechanical, hydraulic, and CNC-controlled models and can be used by small to medium-scale production units, providing flexibility and cost-effectiveness. Used extensively in the pressure vessel manufacturing industry, tank and pipe fabrication, shipbuilding, and construction industries, three-roll machines offer efficient and reliable metal forming solutions for a wide range of industrial applications.

2. Four-Roll Plate Rolling Machines

A rolling machine used in bending of structural metal profiles including angles, beams, channels, and T-sections is utilized to provide shapes with exact curved shapes. Available in both hydraulic and mechanical models, this rolling machine serves very important applications to industries demanding complicated structural forming and high precision within a time limit. Curved metal pieces used in the buildings, bridges, and railway require construction and civil engineering for work. They are also utilized in the mass production of architectural designs through custom metal fabrication to create innovative, functional structural parts. Their capabilities to process profile sizes and types make section rolling machines a staple in the contemporary infrastructure and industrial sectors.

3. Section Rolling Machines

A section rolling machine is a device that specializes in bending metal profiles, including angle, beam, channel, and T-section structural metals into the desired curved forms. Hydraulic and mechanical types of these machines are available and have been proved to be quite indispensable for any industry that deals with complex structural shaping with precision and efficiency. In construction and civil engineering, they are mainly used for building and bridges along with railways in curved metal components. They also play a key role in custom metal fabrication where the architectural design demands creative yet functional structural elements. Section rolling machines have become essential tools for modern infrastructure and industrial projects due to the ability to process different profile sizes and materials.

4. CNC Rolling Machines

CNC is a rolling machine that provides full automation with precise metal rolling in the sense of pre-programmed bending sequences which reduce human errors and improve the efficiency. This machine gives higher repeatability, accuracy, and speed that makes it excellent for the various industries which seek consistent and complicated metal forming. In India, there has been a great rise in using CNC rolling machines. The demand for high quality metal fabrication sheets is increasing day by day and for this purpose there is rise in popularity of Metal rolling machine india.

They can tackle complex designs and many more processes of rolling with less manual interference-a game-changer in modern metalworking and manufacturing.

5. Hydraulic Plate Rolling Machines

Hydraulic plate rolling machines apply pressure on metal sheets through hydraulic force, which ensures rolling is flexible, precise, and consistent. Hydraulic plate rolling machines are quite efficient and powerful compared to mechanical rolling machines. They can roll thicker and tougher sheets of metals that the latter cannot bend efficiently. In that regard, it is possible to generate pressure for more control and precision, reducing the chances of material wastage and increasing productivity. Heavy industries such as oil & gas, shipbuilding, and construction have relied highly on hydraulic plate rolling machines because it helps to bend thick steel plates and manufacture large storage tanks, boilers, and pressure vessels-a perfect tool for modern metal fabrication.

6. Mechanical Rolling Machines

Mechanical rolling machine makes use of gears and motors for driving the rollers- they are highly efficient for light to medium-duty applications but might turn out to be cost-prohibitive for heavy-duty applications. Most SMEs in India prefer such machines on account of its low cost, easy operation, and low maintenance. They are best suited for light sheet metal fabrication, small workshops, and manufacturing units, where precision and efficiency are required without heavy automation. Mechanical rolling machines are widely used in the production of mild steel and aluminum components, which makes them a valuable asset for industries that require basic metal shaping and bending processes at an economical scale.

Conclusion

Metal rolling machine India provides a vast variety of metal rolling machines to cater to various industrial needs. From a simple mechanical machine for small-scale production to an advanced CNC rolling machine for high-precision applications, Indian manufacturers and suppliers provide cost-effective and high-quality solutions for diverse industries. With continuous technological advancements, metal rolling machines are becoming more efficient, automated, and reliable, ensuring a bright future for metal fabrication in India.

Leave a Reply