Introduction

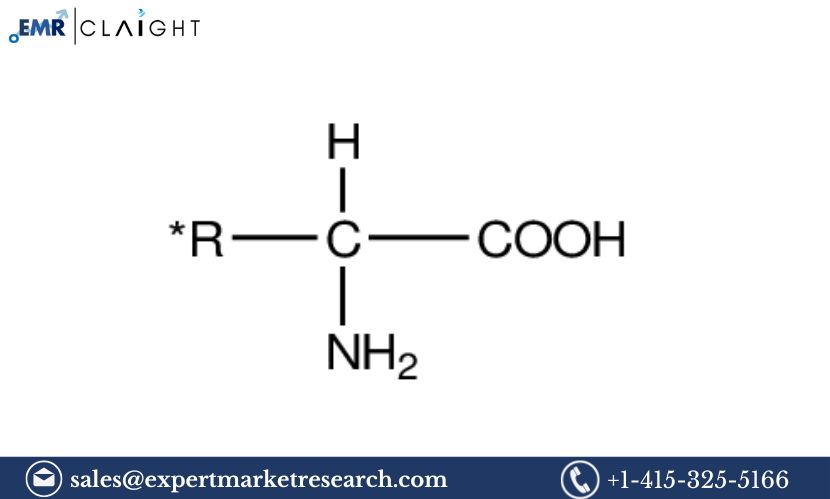

Amino acids are organic compounds that are the building blocks of proteins. They play a crucial role in numerous biological functions, including muscle development, enzyme activity, and immune system support. They are classified into two categories: essential amino acids, which must be obtained through diet, and non-essential amino acids, which the body can synthesize. Amino acids are used in a variety of industries, including pharmaceuticals, food and beverages, animal feed, and cosmetics. The Amino Acid Manufacturing Plant Project Report provides an in-depth analysis of setting up a facility to produce amino acids. This report covers market demand, raw material procurement, manufacturing processes, required infrastructure, and financial projections, making it an essential resource for businesses and investors looking to enter the amino acid production industry.

Market Demand for Amino Acids

The global amino acid market has witnessed significant growth in recent years due to increasing demand from various end-use industries. The primary drivers of this demand include:

-

Pharmaceutical Industry: Amino acids are used in the production of medicines and supplements that treat a variety of health conditions, including metabolic disorders, liver diseases, and muscle disorders.

-

Food and Beverage Industry: Amino acids are added to food products as additives to enhance nutritional value, improve flavor, and aid in food preservation. They are also used in the production of protein supplements and sports nutrition products.

-

Animal Feed: The livestock and aquaculture industries are major consumers of amino acids, especially for the production of high-quality feed. Amino acids such as lysine, methionine, and threonine are used to improve the nutritional value of animal feed.

-

Cosmetic Industry: Amino acids are widely used in skincare and hair care products due to their moisturizing, anti-aging, and nourishing properties.

-

Biotechnology and Research: Amino acids are also used in laboratory research, particularly in the development of therapeutic proteins, enzymes, and other biotechnology products.

The growing demand for amino acids in these industries, coupled with rising consumer awareness about the importance of nutrition and health, makes the amino acid manufacturing sector an attractive investment opportunity.

Get a Free Sample Report with Table of Contents@

Raw Materials for Amino Acid Production

The production of amino acids requires a variety of raw materials, which can vary depending on the type of amino acid being produced. Some common raw materials used in amino acid production include:

-

Glucose or Starch: Glucose or starch is often used as the primary carbon source for microbial fermentation in the production of amino acids such as lysine, glutamic acid, and threonine.

-

Nitrogen Sources: Nitrogen is an essential element for the biosynthesis of amino acids. Nitrogen can be provided in the form of ammonia, ammonium salts, or other nitrogen-rich compounds.

-

Microorganisms: Specific strains of bacteria, yeasts, or fungi are used to ferment raw materials and produce amino acids. Common microorganisms used in amino acid production include Corynebacterium glutamicum, Escherichia coli, and Brevibacterium lactofermentum.

-

Enzymes and Co-factors: Enzymes and co-factors are often required to enhance the fermentation process, increase yield, and ensure the proper synthesis of amino acids.

-

Solvents and Chemicals: Solvents and chemicals such as ethanol, acetone, and sulfuric acid may be used during the purification and extraction processes.

-

Water: Clean water is essential for the fermentation and purification processes, as well as for cleaning and maintaining equipment.

Manufacturing Process of Amino Acids

The production of amino acids typically involves microbial fermentation, followed by separation, purification, and drying. Below is a breakdown of the key steps involved in amino acid production:

1. Fermentation Process

Microbial fermentation is the most common method for producing amino acids. The process begins by inoculating a fermentation vessel with a selected strain of microorganism and providing it with a suitable nutrient medium. The microorganism ferments the carbon and nitrogen sources to produce amino acids.

- Preparation of Media: The growth medium is prepared by mixing glucose or starch, nitrogen sources, and other nutrients required for microbial growth.

- Inoculation: A selected strain of microorganism is inoculated into the fermentation vessel.

- Fermentation: The fermentation process is conducted under controlled conditions of temperature, pH, and oxygen levels. During fermentation, the microorganism converts the carbon and nitrogen sources into amino acids.

2. Separation and Extraction

After fermentation, the next step is to separate the amino acids from the fermentation broth. This is achieved through various methods, including:

- Centrifugation: Centrifuges are used to separate the biomass (cells) from the fermentation broth.

- Filtration: Filtration techniques are employed to remove remaining solid particles.

- Solvent Extraction: Solvents are used to extract the amino acids from the broth. Acetone and ethanol are commonly used in this process.

3. Purification

Once the amino acids have been extracted, they must be purified to remove any remaining impurities or by-products. The purification process may involve several steps, including:

- Ion Exchange Chromatography: This technique is used to separate amino acids based on their charge.

- Crystallization: Crystallization is used to purify amino acids by converting them into solid crystals, which are then filtered and dried.

- Membrane Filtration: Membrane filtration processes like ultrafiltration may be used to concentrate and purify the amino acids.

4. Drying and Packaging

After purification, the amino acids are typically dried to remove any remaining moisture. This step is crucial to ensure the stability and shelf life of the final product.

- Spray Drying: Amino acids are dried by spraying them into a hot chamber where the moisture evaporates quickly.

- Freeze Drying: For more delicate amino acids, freeze-drying may be employed to preserve their structure and activity.

- Packaging: The dried amino acids are packaged in suitable containers such as plastic or glass bottles, bags, or bulk containers, depending on the intended use.

Infrastructure and Equipment

Setting up an amino acid manufacturing plant requires specialized equipment and infrastructure to support the production process. Some of the key equipment and infrastructure required include:

-

Fermentation Tanks: Large bioreactors or fermentation tanks with precise control over temperature, pH, and oxygen levels are essential for microbial fermentation.

-

Centrifuges and Filtration Units: Centrifuges and filtration units are needed to separate the biomass from the fermentation broth and remove solid impurities.

-

Extraction and Purification Systems: Solvent extraction units, chromatographs, and crystallizers are used to extract and purify the amino acids from the fermentation broth.

-

Drying Equipment: Spray dryers or freeze-dryers are required to remove moisture from the amino acids.

-

Quality Control Laboratories: A dedicated lab is necessary for testing the purity, potency, and quality of the amino acids produced.

-

Packaging Lines: Automated packaging machines are needed to efficiently pack the final product in various forms, such as powder, granules, or liquid.

Cost Estimation and Financial Planning

The establishment of an Amino Acid Manufacturing Plant requires significant capital investment, both for infrastructure and for the purchase of raw materials. Below are key cost considerations for setting up the plant:

1. Capital Investment

- Land and Building: The cost of acquiring land and constructing the manufacturing facility.

- Machinery and Equipment: Investment in fermentation tanks, centrifuges, purification systems, drying equipment, and packaging machines.

- Raw Materials: The procurement of glucose, nitrogen sources, microorganisms, and other raw materials required for the fermentation process.

2. Operating Costs

- Labor Costs: Salaries for workers, engineers, technicians, and administrative staff.

- Utilities: Costs for electricity, water, and waste disposal.

- Raw Material Procurement: Ongoing costs for sourcing raw materials like glucose, nitrogen, and microorganisms.

3. Revenue Generation

- Sales of Amino Acids: Amino acids can be sold to pharmaceutical companies, food and beverage manufacturers, animal feed companies, and cosmetic brands.

- Profitability: Profitability depends on the efficiency of the production process, raw material costs, and market demand for amino acids.

Regulatory Compliance and Safety Standards

-

Regulatory Compliance: The manufacturing plant must comply with local and international standards for food, pharmaceutical, and chemical manufacturing. Compliance with Good Manufacturing Practices (GMP) is essential.

-

Environmental Considerations: The plant must implement waste management systems to handle any by-products or waste materials generated during the production process.

-

Safety Standards: Given the chemical nature of the production process, the plant must adhere to strict safety protocols to protect workers and prevent accidents.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

Leave a Reply