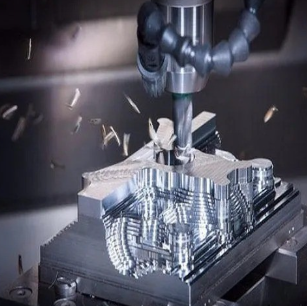

CNC machining is a cutting-edge manufacturing process that allows companies to produce highly accurate and complex parts. Using computer-controlled machines, CNC machining offers unparalleled precision, repeatability, and versatility, making it a preferred choice for industries like aerospace, automotive, and medical.

Key Benefits of CNC Machining:

- Precision and Accuracy: CNC machines deliver parts with tight tolerances, ideal for high-performance applications.

- Flexibility: The ability to create intricate designs and work with a variety of materials makes it a versatile solution.

- Consistency: Once programmed, CNC machines can consistently produce identical parts with minimal variations.

Industries That Benefit from CNC Machining:

- Automotive: Manufacturing high-performance components, from engine parts to suspension systems.

- Aerospace: Creating robust and precise components for aircraft and spacecraft.

- Medical: Producing critical medical devices and implants with strict quality requirements.

How CNC Machining Works:

CNC machining involves several processes, such as milling, turning, and drilling, which are all computer-controlled. These machines follow precise instructions to remove material from a solid workpiece to create a finished part. This process offers flexibility in terms of material selection, from metals and plastics to composites, ensuring that manufacturers can meet their specific needs.

Conclusion

CNC machining has transformed manufacturing by providing speed, precision, and efficiency. This process is integral to the production of complex parts, offering a reliable solution across many industries. To learn more about CNC machining, explore our full guide here.

Leave a Reply