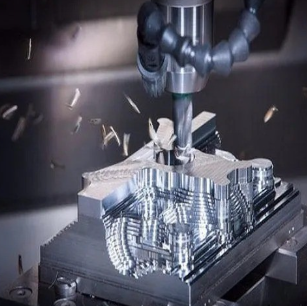

Die casting is a process that allows manufacturers to produce precise, high-quality metal components with remarkable speed. In this technique, molten metal is injected into molds under high pressure, resulting in parts with excellent dimensional accuracy. It is widely used in industries such as automotive, aerospace, and electronics, where strength, durability, and lightweight properties are essential.

Why Die Casting Stands Out

One of the key advantages of die casting is its ability to produce highly complex shapes and detailed features. Parts made using this process often require little to no additional machining, saving both time and costs. The process also ensures minimal material waste, making it cost-effective for large production runs.

Key Benefits of Die Casting

- Precision and Accuracy: Parts are created with tight tolerances, making it ideal for industries where high precision is critical.

- Strong and Durable: Die-cast components are known for their robustness and ability to withstand extreme conditions.

- Efficient Production: Once the mold is made, die casting offers high-speed production with minimal wastage, making it an excellent choice for mass production.

Industries That Use Die Casting

- Automotive: Die casting produces lightweight yet strong components such as engine blocks, transmission parts, and housings.

- Aerospace: The aerospace industry benefits from die casting to create parts that are both durable and lightweight, critical for aircraft components.

- Electronics: The electronic industry uses die casting for creating protective casings for devices like smartphones, laptops, and home appliances.

Challenges in Die Casting

Although die casting offers numerous advantages, there are some challenges. The initial cost of molds can be significant, making it more suitable for large production runs. Additionally, it is typically limited to metals with low melting points, such as aluminum, zinc, and magnesium.

Conclusion

Die casting is a highly effective manufacturing process that combines speed, precision, and durability, making it the go-to choice for industries that require high-quality, complex metal parts. With its cost efficiency in mass production and ability to produce intricate shapes, die casting is set to remain a cornerstone of modern manufacturing.

For further information on the die casting process, check out the full guide here.

Leave a Reply