In the modern manufacturing industry, precision CNC machining has become a cornerstone of high-quality production. Whether in aerospace, automotive, medical, or electronics, this advanced machining process ensures accuracy, consistency, and efficiency. Let’s explore what makes precision CNC machining essential and how it is revolutionizing the way parts and components are manufactured.

What is Precision CNC Machining?

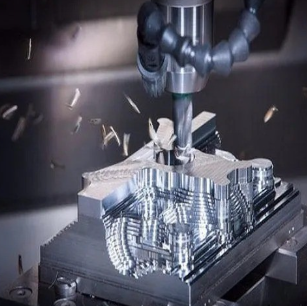

Precision CNC machining is a computer-controlled manufacturing process that produces complex parts with extreme accuracy and tight tolerances. Using advanced software and automated machinery, it eliminates human error and ensures that every component meets exact design specifications.

Benefits of Precision CNC Machining

-

Unmatched Accuracy – CNC machines can achieve micron-level precision, making them ideal for industries that require highly detailed components.

-

Consistency and Reliability – Once programmed, CNC machines produce identical parts repeatedly, ensuring uniformity in production.

-

High Efficiency – By automating manufacturing, CNC machining reduces production time and material waste, leading to cost savings.

-

Versatile Material Compatibility – Capable of machining metals such as aluminum, stainless steel, and titanium, as well as plastics and composites.

-

Enhanced Safety – Automation reduces manual labor, minimizing the risk of human errors and workplace injuries.

Applications of Precision CNC Machining

Due to its versatility and precision, precision CNC machining is used across various industries, including:

-

Aerospace – Manufacturing aircraft components that meet strict safety and performance standards.

-

Medical – Producing surgical instruments, prosthetics, and medical device components.

-

Automotive – Creating engine parts, transmission components, and custom automotive parts.

-

Electronics – Fabricating intricate circuit board components, enclosures, and connectors.

-

Defense – Developing military-grade equipment and specialized components.

Latest Advancements in Precision CNC Machining

With the rapid evolution of technology, precision CNC machining continues to improve. Innovations such as 5-axis machining, AI-powered automation, and real-time monitoring have enhanced precision, efficiency, and production speed. These advancements enable the creation of highly intricate parts while minimizing waste and reducing lead times.

Why Choose Precision CNC Machining?

For businesses that demand accuracy, consistency, and efficiency, precision CNC machining is the go-to solution. Whether for prototypes or large-scale production, this technology ensures top-tier quality and performance.

If you need expert precision CNC machining services, look no further than MXYMachining. Our state-of-the-art equipment and skilled professionals are ready to deliver precision-engineered components tailored to your needs

Leave a Reply