In industries where corrosion, extreme temperatures, and harsh chemicals are prevalent, the need for durable, efficient, and long-lasting equipment is essential. PTFE (Polytetrafluoroethylene) lining is a revolutionary material that meets these challenges by providing superior protection against wear and tear. By offering remarkable resistance to chemical reactions and extreme conditions, PTFE lining has become indispensable in many sectors, from chemical processing to food production and pharmaceuticals. In this blog, we will discuss the significant advantages of PTFE lining, its applications, and why it’s become a staple in modern industrial equipment.

Understanding PTFE Lining

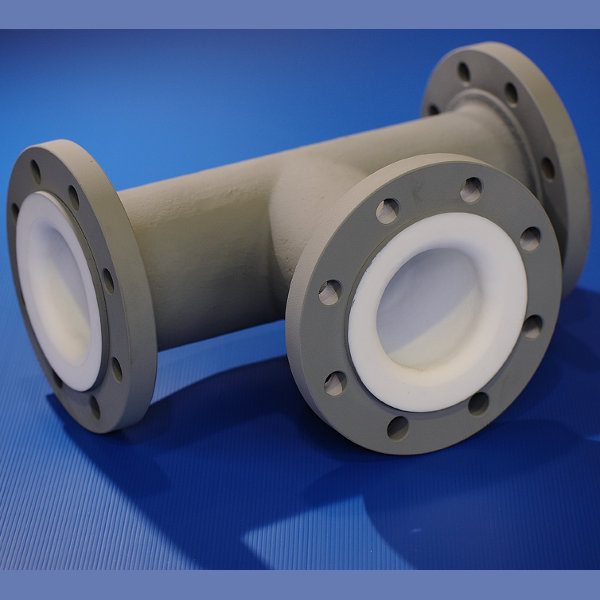

PTFE is a synthetic fluoropolymer with extraordinary properties, including chemical inertness, non-stick characteristics, and thermal stability. PTFE lining involves applying a layer of PTFE to the interior surfaces of equipment such as pipes, tanks, vessels, and reactors to protect them from corrosion, enhance flow efficiency, and extend the lifespan of the machinery.

A widely known brand of PTFE is Teflon, which was first developed by DuPont in the 1940s. PTFE’s properties have since made it essential in various industries that require high-performance materials for processing harsh chemicals, heat-sensitive operations, and sterile environments.

Key Properties of PTFE

PTFE’s exceptional properties are the reason it’s chosen as a lining material across a broad range of industries. Let’s take a closer look at the features that make PTFE a standout material:

-

Chemical Resistance: PTFE is highly resistant to a broad range of aggressive chemicals, acids, alkalis, and solvents. Its inert nature makes it immune to chemical reactions, which is crucial for protecting equipment in corrosive environments.

-

Non-Stick Surface: One of PTFE’s most well-known characteristics is its extremely low coefficient of friction. This makes it non-stick, preventing materials from adhering to surfaces, improving flow, and minimizing blockages in equipment.

-

Thermal Stability: PTFE is capable of withstanding high temperatures without degrading. Its melting point is around 327°C (621°F), and it can maintain its properties in both extremely hot and cold environments, ensuring performance under varying temperature conditions.

-

Electrical Insulation: PTFE’s excellent electrical insulating properties make it a go-to material in electrical and electronics applications, preventing energy loss and reducing the risk of electrical faults.

-

Durability and Wear Resistance: PTFE is extremely durable and resistant to wear, ensuring that equipment with PTFE linings lasts much longer compared to those without, which reduces maintenance and replacement costs over time.

Key Benefits of PTFE Lining

PTFE lining provides a host of benefits that make it the ideal solution for many industries. Below are some of the most important advantages:

1. Superior Corrosion Protection

In industries like chemical processing, where equipment frequently comes into contact with corrosive substances, PTFE lining offers unparalleled protection. Its chemical inertness means that it does not react with most chemicals, thus preventing corrosion and protecting valuable equipment from degradation. This significantly reduces the need for frequent replacements and costly repairs.

2. Enhances Process Efficiency

The non-stick and smooth nature of PTFE ensures that liquids, gases, or powders do not adhere to the lining. This leads to better flow, preventing clogs, buildups, and process interruptions. By improving the flow rate, PTFE linings help maintain smooth operations and higher efficiency in industrial processes.

3. Improved Safety

The application of PTFE lining reduces the risk of accidents or hazardous leaks. In industries handling dangerous chemicals or extreme temperatures, the protective lining ensures that the integrity of the equipment is maintained, thus reducing the likelihood of costly and dangerous failures.

4. Energy and Cost Savings

Although the initial investment in PTFE-lined equipment may be higher, the long-term savings are significant. By extending the life of equipment, reducing downtime, and cutting down on maintenance needs, PTFE lining provides a return on investment through minimized operational costs.

5. Hygiene and Easy Maintenance

In industries such as food processing and pharmaceuticals, hygiene is critical. PTFE linings make it easier to clean equipment because the non-stick surface prevents materials from sticking and accumulating. The smooth surface also reduces the potential for bacterial growth, making PTFE-lined equipment ideal for sterile environments.

Applications of PTFE Lining

PTFE lining is widely used across multiple industries for its ability to withstand chemical and thermal stress. Here’s a closer look at some of the most common applications:

1. Chemical and Petrochemical Industries

In these sectors, PTFE-lined pipes, tanks, and reactors are crucial for handling corrosive chemicals, acids, and solvents. PTFE ensures that equipment remains resistant to corrosion, wear, and chemical degradation, which is vital for maintaining safe, efficient operations in chemical plants and refineries.

2. Pharmaceutical and Biotech Industries

The pharmaceutical industry relies on PTFE-lined equipment to ensure purity, avoid contamination, and maintain high standards of cleanliness. PTFE lining prevents chemical reactions with sensitive drugs, allowing for safe storage and transport of pharmaceutical products. Additionally, PTFE is resistant to bacterial growth, making it ideal for sterile environments.

3. Food and Beverage Processing

In the food industry, PTFE lining is used in tanks, pipelines, and mixers to prevent food products from sticking to equipment and to simplify cleaning processes. The material also complies with hygiene regulations, ensuring safe food processing and minimizing contamination risks.

4. Oil and Gas Industry

PTFE linings are critical in the oil and gas industry, where equipment such as valves, pumps, and storage tanks need to withstand corrosive materials and high temperatures. The lining helps protect the infrastructure, extending its useful life and minimizing the need for repairs.

5. Electronics and Electrical Equipment

In the electronics industry, PTFE is used as insulation for wires, cables, and components due to its high dielectric strength and resistance to heat. This ensures the efficient operation of sensitive electronic devices and systems.

The PTFE Lining Application Process

The process of applying PTFE lining to equipment is an intricate one that involves several key steps:

-

Surface Preparation: The equipment’s surface must be thoroughly cleaned and prepared to ensure the PTFE adheres properly. This is usually done by abrasive blasting or other mechanical methods to ensure a rough surface that promotes adhesion.

-

Application: PTFE can be applied in different forms, including powder, paste, or sheet lining. The method chosen depends on the specific equipment and the application’s requirements.

-

Curing: Once the PTFE is applied, it is cured in an oven at high temperatures to bond the material to the surface and create a strong, durable layer.

-

Inspection and Testing: After curing, the lined equipment undergoes rigorous testing and inspection to ensure the PTFE lining is intact, free from defects, and capable of withstanding the conditions it will be exposed to.

Conclusion

PTFE lining is a versatile, reliable, and cost-effective solution for enhancing the performance and durability of industrial equipment. Whether in chemical processing, food production, or pharmaceuticals, PTFE-lined equipment ensures long-term reliability, improved efficiency, and enhanced safety. With its outstanding properties, including chemical resistance, heat tolerance, and non-stick characteristics, PTFE is a critical material that industries continue to rely on for robust, long-lasting equipment. If you’re looking for ways to improve your operational efficiency and reduce maintenance costs, PTFE lining is an investment worth considering.

Leave a Reply