With respect to forming a trustworthy electronics using thermal management techniques, MCPCB or metal core PCB is one of the favorite parts in this industry. More specifically, it is noted as the most impressive and strongest boards for lighter LED lighting applications, power supplies, and automotive electronics compared to standard PCBs.

One of the most crucial decisions you would have to make in the marketplace of metal core PCBs is to choose a good manufacturer to realize your designs. However, evaluating and selecting a partner from thousands of options isn’t easy. So, let’s explore further.

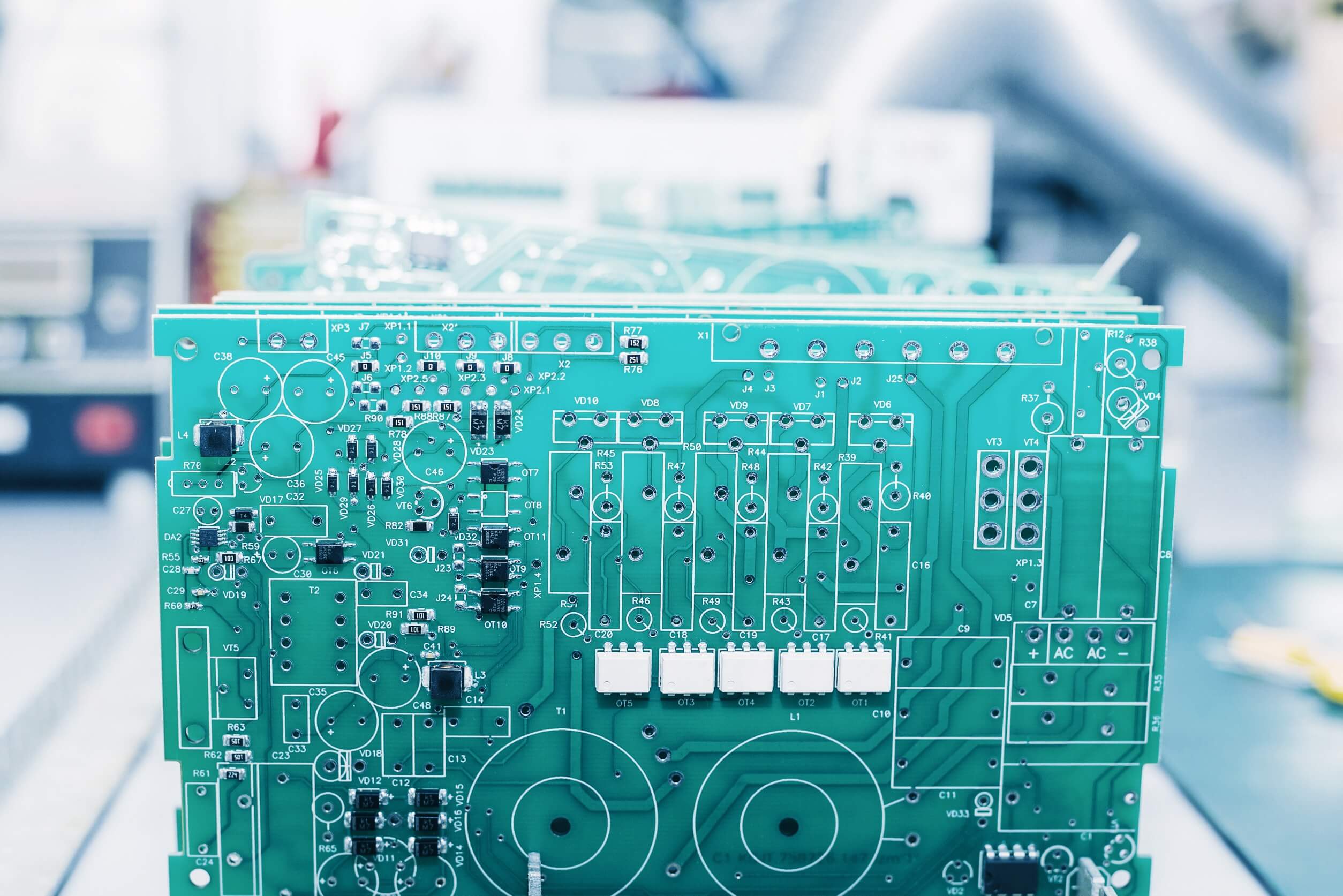

What is a Metal Core PCB?

It is a type of printed circuit board that includes a metal layer usually made of aluminum, copper, or an alloy in its core. This core metal plays an important role in allowing the heat generated by high-power components to dissipate out from the board, which is why such boards are essential for applications demanding efficient thermal management. Key Features of MCPCBs:

- Thermal Conductivity: Heat is drawn out from the key components by a metal layer preventing overheating and ensures reliability.

- Strength and Durability: These PCBs are made stronger than any traditional PCB and can be designed to withstand environmental conditions.

- Application Specificity: Widely used in areas such as LED lighting, automobile, industrial, and renewable energy systems.

Whichever product being manufactured is whether floodlights, audio amplifiers, or modules, MCPCBs are vital for consistent operation and long-life.

Now that you are aware of what makes MCPCBs unique, it is time to narrow down the search for a suitable manufacturing partner.

Selecting the Best MCPCB Manufacturing Company

The extent to which your final product turns out depends on the accuracy and quality of the MCPCBs used. Choosing the right MCPCB company means you are selecting a partner capable of meeting your technical requirements, timeline, and budget while also delivering top-quality work. The following represent the most important factors to consider:

- Expertise and Experience

Start by evaluating how experienced the company is in manufacturing MCPCBs. Look for signs that indicate their expertise:

- Years of experience producing metal core PCBs.

- A portfolio that includes projects similar to your industry or application.

- Certifications like ISO 9001 or compliance with IPC standards.

An experienced MCPCB manufacturer won’t just produce your design; they’ll offer valuable input to ensure optimal thermal performance and manufacturability.

- Material Options

Not all metal core PCBs are created equal. Materials used play a huge role in their performance. The manufacturer should provide flexibility on material selection options such as the following:

- Aluminum: Great for cost-effective and common uses like LED lighting.

- Copper: Offers better thermal conductivity and durability, making it best for high power applications.

- Alloys: Solution tailored to certain industries where special thermal properties become the requirement.

Inquire from the potential partners about their ability to customize material layers according to your needs.

- Production Capabilities

Does the manufacturer have the technology to handle your project specifications? The best MCPCB manufacturers invest in cutting-edge production facilities that can execute precise designs accurately and efficiently. Consider the following capabilities:

- Single-layer or multi-layer MCPCB production.

- High-precision drilling and milling machines.

- Advanced thermal interface materials that enhance performance.

- Quality Assurance Processes

A manufacturer’s quality commitment is non-negotiable. Look for companies which have a very strict quality control process and include things like:

- Testing Procedures: Such as 100% E-testing on every board to ensure there are no electrical issues.

- Thermal Conductivity Testing: To provide evidence that the board complies with the set thermal performance requirements.

- Inspection Equipment: High-tech devices such as X-ray or AOI machines that catch defects before shipping.

Top companies should be transparent about their quality protocols and provide certifications showing that they do indeed care about excellence.

- Customization and Design Support

Designing MCPCBs can be challenging. Good manufacturers typically offer design support to ensure that your layout has the best manufacturability while satisfying your project’s needs. This may include:

- Suggestions for stack-up configurations.

- Thermal simulations for efficient heat management.

- Expert feedback on material selection and component placement.

Select a supplier that is more of a collaborative partner than just a vendor. A support-focused company can be an innovative provider of solutions to optimize performance and cost.

- Cost Transparency

Even though cost effectiveness is important, extremely low-priced items may be suspect for compromised quality. Ensure the manufacturer is transparent on costs, including being clear on the following:

- MOQs

- Prototyping cost versus mass production rate.

- Costs associated with material upgrades or testing procedures.

Transparent pricing will keep you away from surprises during production and ensure that your budget is in check.

- On-Time Delivery

Time-to-market is what makes or breaks any project. Work with a company that is known to stick to its delivery timelines. Here is what you should check for

- Lead times for prototype and mass production.

- Ability to produce urgent orders without compromising quality.

- Based on customer reviews or case studies.

- Customer Reviews and Reputation

Last but not the least, do not believe what a manufacturer says. Know how they are perceived in the industry. Read testimonials, case studies, and online reviews to know their reputation.

- Are they being talked about for quality, customer service, and dependability?

- Do they have repeat customers or long-standing partnerships that indicate trustworthiness?

Conclusion

Metal core PCB is the backbone of modern electronics, where thermal performance is crucial; the groundwork for a successful product rollout and lasting competitive advantage is being laid with time invested in selecting the right manufacturing partner.

Whether you are just starting or looking to scale up, the right MCPCB company will make all the difference in turning your designs into high-performing, durable products. Take your time, ask questions, and make a choice that aligns with your project’s vision and values.

Leave a Reply