As industries increasingly embrace sustainable practices, materials that offer both efficiency and environmental benefits are in higher demand than ever. Among these, polypropylene (PP) fibrillated yarn stands out for its versatility and eco-friendly characteristics. This article delves into the various environmental advantages of PP fibrillated yarn, particularly in the context of waste reduction, durability, and resource efficiency. Furthermore, we will highlight the efforts of key players in the market, including notable fibrillated yarn suppliers and manufacturers based in Ahmedabad and across India.

Understanding PP Fibrillated Yarn

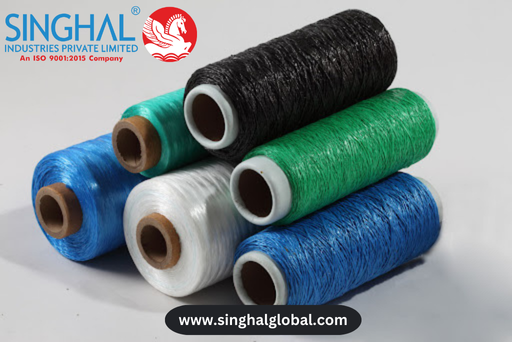

PP fibrillated yarn is produced by splitting polypropylene filaments into thin fibers. This unique process creates a network of interconnected strands that enhances the fabric’s strength and texture while also enabling it to retain its shape. These properties make PP fibrillated yarn particularly suitable for a wide range of applications, from geotextiles to agricultural covers and packaging.

Source Reduction and Waste Minimization

One of the most significant environmental advantages of PP fibrillated yarn is its long-lasting nature. Traditional materials may require frequent replacements, leading to increased waste. In contrast, products made from PP fibrillated yarn boast exceptional durability, prolonging their lifespan.

For instance, in agricultural settings, using PP fibrillated yarn for crop covers or netting can reduce the frequency of replacement, thereby lowering plastic waste in the soil and surrounding environment. This characteristic not only mitigates landfill contributions but also minimizes the need for production of new materials.

Lightweight Yet Strong

The lightweight nature of PP fibrillated yarn is another contributing factor to its environmental benefits. Because it requires less energy to transport and handle, the carbon footprint associated with logistics is significantly diminished. When looking for a Polypropylene yarn supplier in Ahmedabad, manufacturers often emphasize the lightweight properties of their products, which translates to less fuel consumption and reduced greenhouse gas emissions across the supply chain.

Additionally, its high tensile strength ensures that the material can withstand harsh conditions, further enhancing its lifecycle and reducing the need for replacements. All these factors compound to create a more sustainable approach to materials in various industries.

Resource Efficiency in Production

PP fibrillated yarn is primarily made from polypropylene, which is derived from petroleum. While this may raise concerns about fossil fuel dependence, the production process has seen significant improvements in energy efficiency. Advanced manufacturing techniques employed by Polypropylene yarn manufacturers in India have led to reduced energy consumption, making the production of PP fibrillated yarn more environmentally friendly.

Moreover, many suppliers are now adopting circular economy principles. Waste materials from other manufacturing processes are often repurposed to create PP yarns, further contributing to resource efficiency. The growing awareness among polypropylene yarn suppliers in Ahmedabad about sustainable practices is paving the way for a more responsible industry.

Biodegradable Alternatives and Innovations

Although PP itself is a synthetic material that does not naturally decompose, the commitment to developing biodegradable alternatives within the industry is growing. Several innovative companies are researching and implementing biopolymer technologies to produce biodegradable yarns, which can complement or eventually replace traditional PP products.

While this is still in the developmental phase, the interest and investment in sustainable materials signal a promising future for the textile and manufacturing sectors. The integration of these innovative solutions aims to align with the global movement toward reducing plastic pollution and environmental degradation.

Conclusion

The environmental benefits of PP fibrillated yarn are numerous and compelling. From its durability and lightweight properties to innovative manufacturing practices and resource efficiency, PP fibrillated yarn presents a practical solution for a variety of applications. As awareness about environmental sustainability increases, the demand for eco-friendly materials like PP fibrillated yarn will likely continue to rise.

For businesses looking to adopt more sustainable practices, exploring partnerships with reputable Fibrillated yarn supplier in Ahmedabad and polypropylene yarn manufacturers in India can serve as a vital step toward supporting an eco-conscious supply chain.

Frequently Asked Questions (FAQs)

1. What applications are best suited for PP fibrillated yarn?

PP fibrillated yarn is highly versatile and is used in various applications, including geotextiles, agricultural covers, tarpaulins, ropes, and nets. Its strength and durability make it particularly effective for outdoor and heavy-duty uses.

2. How does PP fibrillated yarn compare to other synthetic yarns in terms of sustainability?

While most synthetic yarns have environmental drawbacks, PP fibrillated yarn offers significant advantages, including longer lifespans and reduced waste. Furthermore, advancements in production techniques are making it more energy-efficient, and the exploration of biodegradable options may enhance its sustainability profile.

3. Where can I find reliable suppliers of PP fibrillated yarn in Ahmedabad?

There are several reputable fibrillated yarn suppliers in Ahmedabad, as well as other regions in India, where you can source high-quality PP yarn. Research local suppliers, read customer reviews, and inquire about sustainable practices to find a company that aligns with your environmental goals.

By making informed choices and advocating for sustainable materials in your procurement processes, you can contribute to a more environmentally friendly future while still meeting your business needs.

Leave a Reply